July 6, 2017 4 min read

Wire Rope: Lay, Classification, and Construction

Industry:

Solution:

Working safely with wire rope, for rigging and other purposes, requires an understanding of some of the characteristics of wire rope. Characteristics you should understand include lay, classification, and construction. We’ll explain each in this article.

For even more information about wire rope, please see our wire rope online training video and wire rope safety online training video courses.

Vector EHS Management Software empowers organizations – from global leaders to local businesses – to improve workplace safety and comply with environmental, health, and safety regulations.

Learn more about how our software can save you valuable time and effort in recording, tracking, and analyzing your EHS activities.

Learn more about how we can help:

- Incident Management Software →

- EHS Inspection Software →

- Key Safety Metrics Dashboard →

- Learning Management System (LMS) and Online Training Courses →

- Mobile Risk Communication Platform

Download our EHS Management Software Buyer’s Guide.

Wire Rope: Parts

In this article, we’re going to tell you what it means to discuss a wire rope’s lay, classification, and construction.

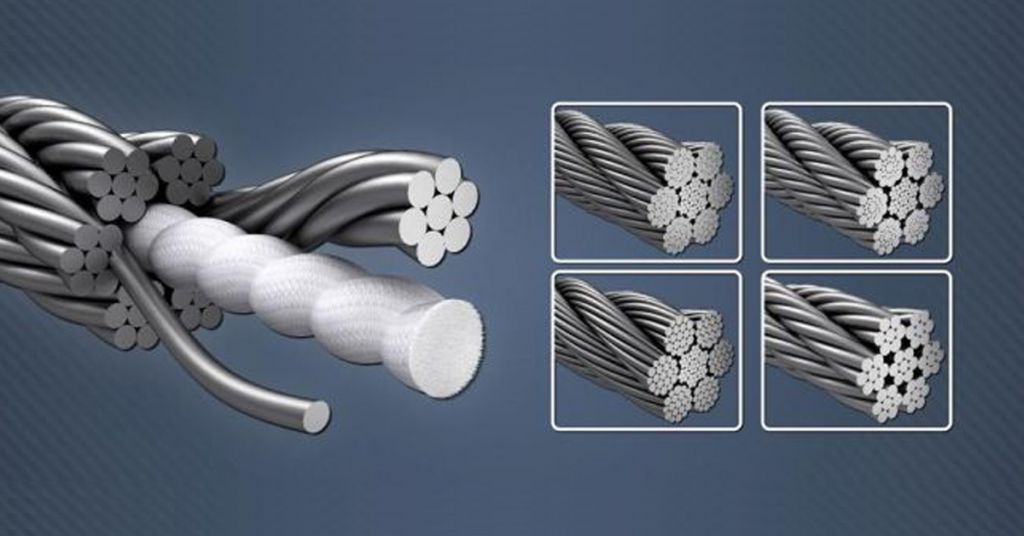

But to understand those characteristics of a wire rope, it’s important to know that a wire rope has three parts:

- The core at the center of the rope

- Strands, which are groups of individual wires that wrap around the core

- Wires, which are single, individual pieces of metal that are drawn to a small diameter and are grouped to make the strands

This is illustrated in the video sample below form our online wire rope training video.

Wire Rope Lay

The idea of “lay” is used to describe three different characteristics of wire rope.

The first is the direction in which the wire rope’s strands are wrapped around the wire rope’s core. This can be either left or right.

The second is the relationship between the direction in which the strands are wrapped around the core and the direction that the wires within the strand are wrapped. This can be regular or lay.

And the third is the linear, or straight-line, distance a strand travels while making a single revolution around the core of the wire rope. This is known as the lay length.

The three meanings of lay are illustrated in the short sample video below, taken from our wire rope basics online course.

The different lays and lay lengths of wire rope all have a functional purpose, and wire ropes with specific lays have different advantages and disadvantages for specific applications at work.

Wire Rope Classification

Another way to characterize wire rope is by the number of wires in each strand and the number of strands in the rope itself. This is known as wire rope classification.

A wire rope’s classification includes two numbers (such as 6 x 19). The first number (6, in this example) represents the exact number of strands in the rope. The second number represents the number of wires in each strand, but this number identifies a class, or range and may not be an exact number of wires. For example, a 6 x 19 class wire rope always has six strands, but may have 15-26 wires in each strand.

This is illustrate more fully in the short sample video below, taken from our wire rope elearning course.

Wire Rope Construction

In addition to lay and classification, wire rope is also characterized by its construction.

The construction of a wire rope describes how the wires within each strand are arranged. There are four common types of construction for wire ropes:

- Single layer

- Seale

- Filler wire

- Warrington

The video sample below illustrates this in more detail.

For more specifics about wire rope construction, including the four types and their typical uses, please see our wire rope online training video.

Summary: Wire Rope Lay, Classification, and Construction

Hope you found this brief introduction to some aspects of wire rope, including the different parts of a wire rope and the rope’s lay, classification, and construction, helpful.

Remember there’s a lot more to learn about wire rope in order to work with it properly and safely, and thankfully, we offer two online learning courses for it–our wire rope basics online course and our wire rope safety and operations online course.

And of course, we’ve got courses on rigging and cranes and similar topics in our online health and safety training library, which is geared for manufacturing clients and features our hallmark animated style, including 3-D.

Let us know if you have any questions. The comments field below awaits you. Otherwise, have a great day and keep in touch.

Risk Management Guide for Safety

Learn to use risk-management approaches for safety and health management.

Download Now