July 30, 2024 2 min read

What Is Mechanical Maintenance?

Industry:

Solution:

Mechanical Maintenance is the systematic process of inspecting, servicing, and repairing machinery and equipment to ensure its reliable and efficient operation, extend its lifespan, and prevent unexpected failures. It is a critical aspect of ensuring the smooth operation of machinery and equipment across multiple industries including Manufacturing, Mining, Oil & Gas, and Construction.

In this article, we’ll explore the different types of mechanical maintenance, key components, the role of technicians, training and certifications, and the impact of technology on the industry.

Types of Mechanical Maintenance

Mechanical maintenance can be categorized into several key types, each serving a distinct purpose in ensuring equipment reliability and performance. These types include:

- Preventive Maintenance

- Predictive Maintenance

- Corrective Maintenance

- Scheduled Maintenance

- Unscheduled Maintenance

1. Preventive Maintenance

Preventive maintenance involves regularly scheduled activities aimed at preventing equipment failures before they occur. This proactive approach includes routine inspections, servicing, and component replacements based on manufacturer recommendations or operational history. By addressing potential issues before they escalate, preventive maintenance helps reduce unplanned downtime and extends the life of machinery.

2. Predictive Maintenance

Predictive maintenance uses advanced data analysis and diagnostic tools to forecast when equipment is likely to fail. Techniques such as vibration analysis, thermal imaging, and oil analysis provide insights into equipment condition, allowing for timely interventions. This method helps optimize maintenance schedules and minimize unnecessary maintenance tasks.

3. Corrective Maintenance

Corrective maintenance is performed after equipment has failed or malfunctioned. The primary goal is to restore the equipment to its operational state. While necessary, corrective maintenance often results in unexpected downtime and can be more costly compared to preventive or predictive maintenance. However, it is crucial for addressing issues that arise unexpectedly.

4. Scheduled Maintenance

Scheduled maintenance refers to routine servicing tasks carried out at predetermined intervals, regardless of the equipment’s current condition. These tasks are typically based on operational hours, calendar dates, or usage patterns. Scheduled maintenance helps ensure that equipment remains in good working order and adheres to manufacturer guidelines.

5. Unscheduled Maintenance

Unscheduled maintenance is required when equipment fails unexpectedly and requires immediate attention. This type of maintenance is often reactive and can disrupt operations. Effective management of unscheduled maintenance involves having contingency plans and rapid response strategies to minimize operational impact.

Customizable Training Plans for Maintenance Teams

Use our learning path tool to quickly assign eLearning courses to help fill skill gaps, onboard employees faster, and help employees level up their careers.

Download Training Plan

Key Components of Mechanical Maintenance

The key components of mechanical maintenance ensure that equipment remains in optimal working condition. These components include:

- Inspection

- Lubrication

- Adjustment

- Replacement

- Cleaning

Each of these elements plays a crucial role in maintaining machinery and preventing failures. Let’s look at each component to understand their importance and how they contribute to effective mechanical maintenance.

Inspection

Regular inspections are fundamental to mechanical maintenance. They involve examining equipment for signs of wear, damage, or operational issues. Inspections help identify potential problems early, allowing for timely corrective actions.

Lubrication

Lubrication reduces friction between moving parts, preventing excessive wear and tear. Proper lubrication is essential for maintaining optimal equipment performance and longevity. Maintenance technicians must ensure that lubricants are applied correctly and at the right intervals.

Adjustment

Equipment often requires adjustments to maintain optimal performance. This may involve calibrating settings, tightening or loosening components, and aligning parts. Regular adjustments ensure that machinery operates efficiently and reduces the risk of malfunctions.

Replacement

Over time, components may become worn or damaged and need replacement. Timely replacement of parts helps prevent equipment failures and maintains operational efficiency. A well-managed inventory of spare parts is crucial for minimizing downtime during replacements.

Cleaning

Cleaning machinery and equipment is essential for removing debris, contaminants, and buildup that can affect performance. Regular cleaning helps prevent malfunctions and extends the life of equipment by reducing the risk of corrosion and damage.

Duties of a Mechanical Maintenance Technician

Mechanical maintenance techs are responsible for conducting regular inspections, troubleshooting issues, repairing or replacing equipment, and accurately documenting at every step of the way. Let’s go into each responsibility in more detail.

Routine Inspections

Mechanical maintenance technicians perform regular inspections to monitor the condition of equipment. This includes checking for signs of wear, abnormal noises, or performance issues. Inspections help identify problems early and ensure that equipment remains in good working order.

Troubleshooting

When equipment malfunctions, technicians diagnose the root cause of the issue. Troubleshooting involves analyzing symptoms, testing components, and determining the necessary repairs or replacements. Effective troubleshooting minimizes downtime and restores equipment functionality.

Repairs and Replacements

Technicians carry out repairs and replace faulty components as needed. This may involve disassembling machinery, fixing or replacing parts, and reassembling equipment. Skilled technicians ensure that repairs are performed accurately and efficiently.

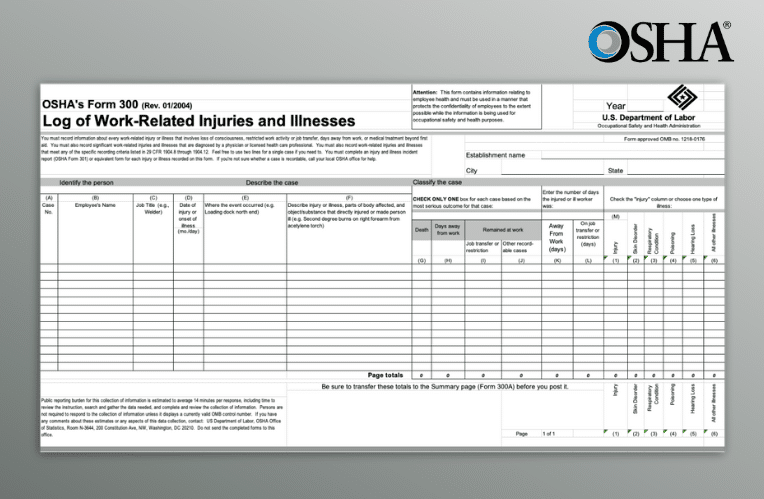

Documentation

Accurate documentation of maintenance activities is essential for tracking equipment performance and maintenance history. Technicians record details of inspections, repairs, and replacements, providing valuable information for future maintenance planning.

Collaboration

Mechanical maintenance technicians often work with other team members, including engineers and operations staff, to address equipment issues and implement maintenance strategies. Collaboration ensures that maintenance activities align with operational goals and standards.

Training and Certification for Mechanical Maintenance Technicians

Certifications

Certifications are essential for proving a technician’s skills and advancing their career in mechanical maintenance. Key certifications include the Certified Maintenance & Reliability Technician (CMRT) and HVAC certifications.

The CMRT certification, offered by the Society for Maintenance & Reliability Professionals (SMRP), validates expertise in maintenance practices and equipment reliability.

HVAC certifications focus on the knowledge needed for maintaining heating, ventilation, and air conditioning systems. These credentials not only confirm technical skills but also enhance professional credibility and job prospects.

Training Programs for Mechanical Maintenance Technicians

Training programs provide practical experience and essential knowledge for mechanical maintenance technicians. They cover topics such as equipment operation, diagnostics, troubleshooting, and safety procedures. These programs can include hands-on practice or 3D simulations to develop problem-solving skills.

Ongoing training ensures technicians are updated with the latest technologies and best practices, enhancing their effectiveness and adaptability.

Commercial Facilities Maintenance Training Library

This fully 3D animated library will properly train facilities maintenance technicians and building engineers on how to safely perform preventive maintenance tasks and corrective repair at commercial facilities.

View Library

Continuing Education

Continuing education is essential for keeping skills up-to-date in the evolving field of mechanical maintenance. Technicians should pursue additional certifications, workshops, and courses to stay current with emerging technologies and practices.

Utilizing education tracking features in a Learning Management System (LMS) ensures that technicians’ ongoing learning is effectively monitored, helping them remain proficient and competitive in their roles.

Role of Technology in Modern Mechanical Maintenance

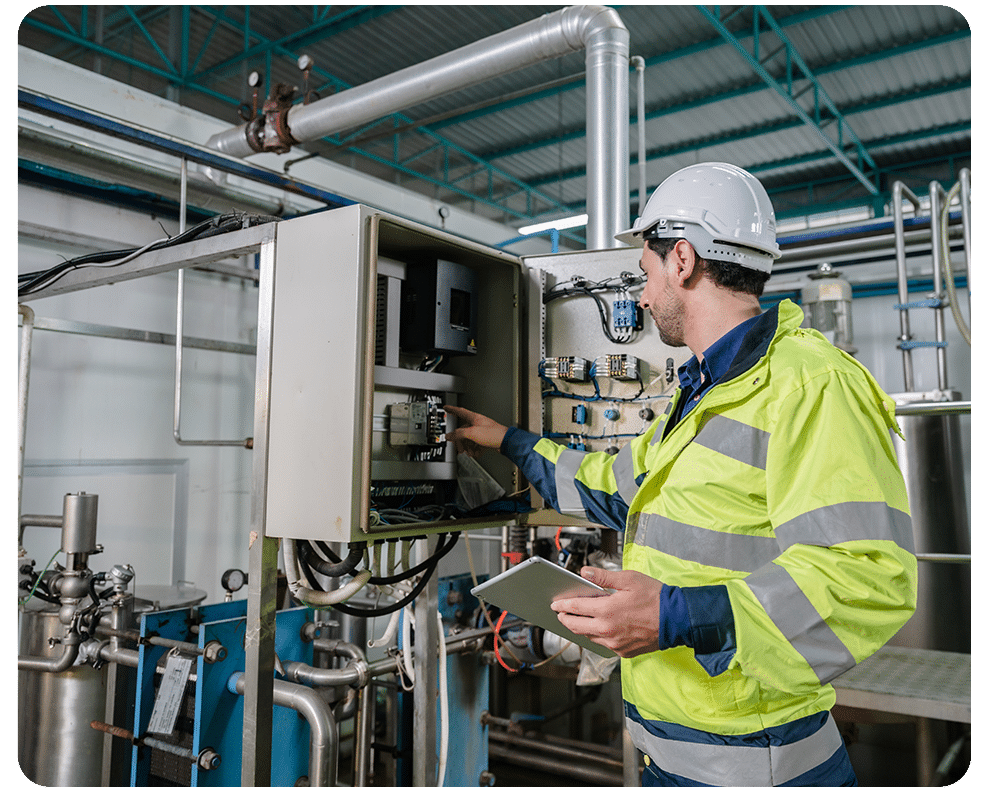

Automation and Control Systems

Automation and control systems play a significant role in modern mechanical maintenance. These systems monitor equipment performance, adjust settings, and provide real-time data on operational conditions. Automation enhances efficiency and reduces the need for manual interventions.

Condition Monitoring Tools

Condition monitoring tools, such as vibration sensors and thermal cameras, allow for continuous assessment of equipment health. These tools provide valuable data that helps technicians identify potential issues and perform targeted maintenance.

Maintenance Management Software

Maintenance management software facilitates scheduling, tracking, and managing maintenance tasks. These tools streamline maintenance workflows, improve communication, and provide insights into equipment performance and maintenance history.

Data Analytics

Data analytics leverages large datasets to identify patterns, trends, and potential issues in equipment performance. By analyzing historical data, technicians can make informed decisions and optimize maintenance strategies for better outcomes.

Challenges and Future Trends in Mechanical Maintenance

Common Challenges

Mechanical maintenance faces several challenges that can impact efficiency and effectiveness.

- Skill shortages pose a significant issue, as finding qualified technicians becomes increasingly difficult.

- Equipment obsolescence also presents a challenge, as older machinery may lack compatibility with new technologies and require costly upgrades.

- Budget constraints can further limit the ability to invest in necessary maintenance tools and technologies.

Addressing these challenges requires strategic planning, increased investment in technician training, and a proactive approach to adopting new technologies and methodologies to enhance maintenance practices and ensure long-term operational success.

Future Trends

Emerging trends in mechanical maintenance are set to transform the industry by leveraging cutting-edge technologies. The integration of artificial intelligence (AI) is revolutionizing maintenance through advanced predictive analytics, which helps anticipate equipment failures before they occur. Additionally, the Internet of Things (IoT) is enhancing maintenance capabilities with sensors that provide real-time data on equipment performance.

These innovations enable more precise monitoring, proactive maintenance, and improved decision-making. As these technologies continue to evolve, they promise to significantly enhance maintenance practices, drive operational efficiency, and create new opportunities for innovation in the field.

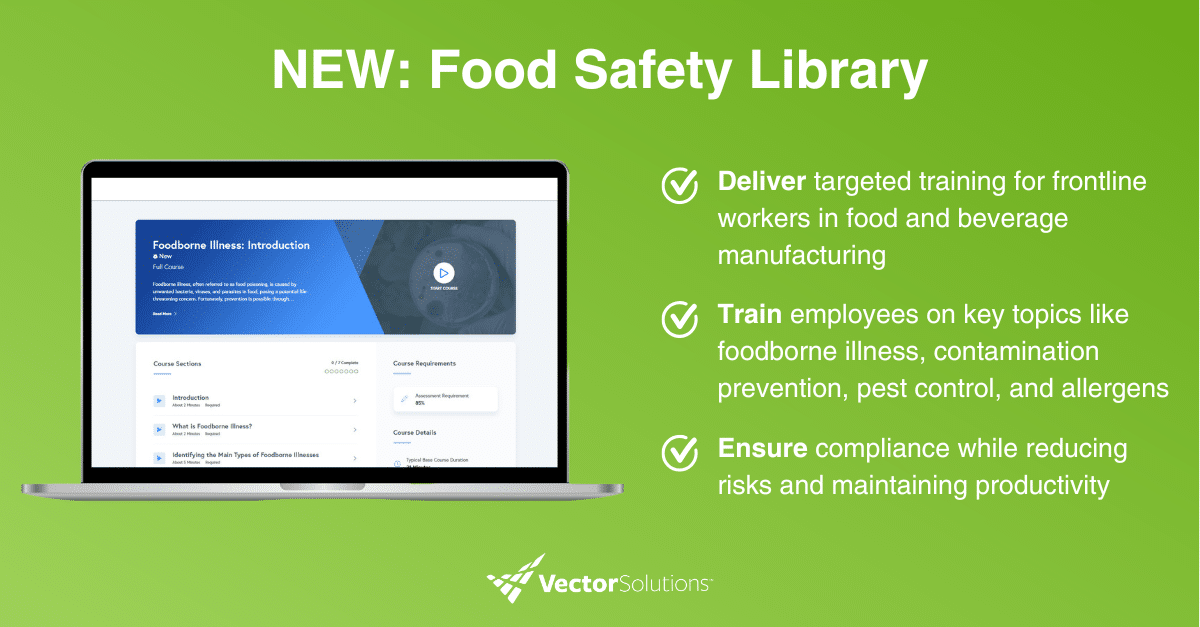

Why Choose Vector Solutions for Your Maintenance Training?

Mechanical maintenance is essential for ensuring the reliability and efficiency of machinery and equipment. By understanding the different types of maintenance, key components, and the role of technicians, organizations can develop effective maintenance programs that reduce downtime and extend equipment lifespan. Embracing technology and staying informed about industry advancements will further enhance maintenance practices and drive operational success.

Vector Solutions is an industry leader in maintenance training with 2000+ high-quality online skills and safety training courses, supported in 46+ languages. Ensure your maintenance technicians and building engineers have the technical skills they need to effectively maintain building integrity, enhance occupant safety, and preserve property value.

Interested in learning more about Vector Solutions’ training and safety management solutions? Request a demo today to see them in action.

The Power of Online Maintenance Training Guide

Download our Power of Online Maintenance Training Guide to uncover the impacts on hiring, skills development, performance and productivity.

Download Guide