July 23, 2017

OSHA Personal Protective Equipment (PPE) Standards and Requirements

Industry:

Solution:

- Learning Management Systems

- Online Safety and Health Training Courses

- EHS & Safety Management Software

- Mobile Apps for Safety Management and Safety Training

If PPE Prevents Injuries, Why Are So Many Workers Still Getting Hurt?

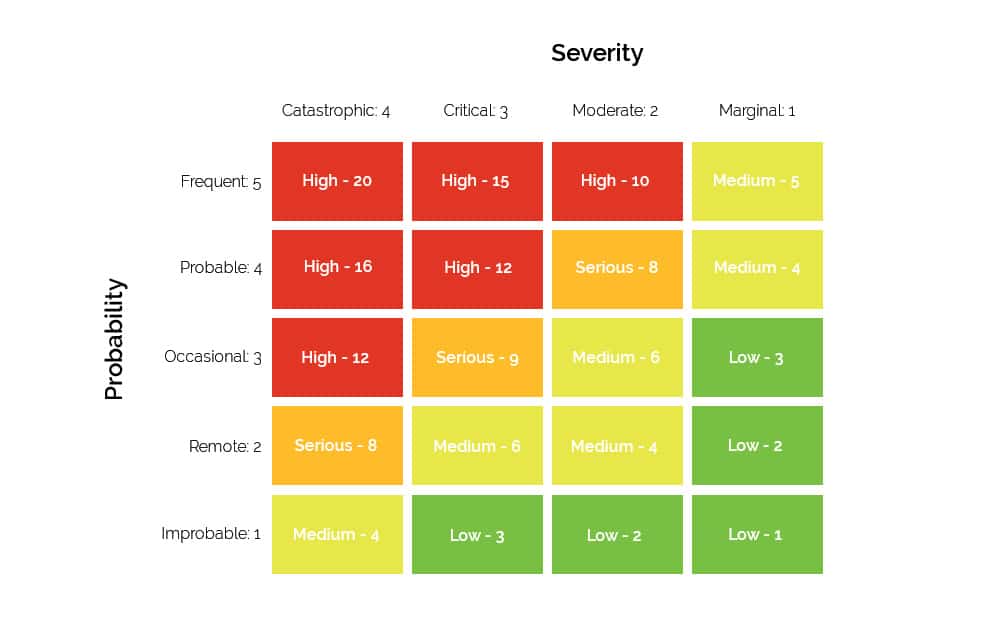

Often, the answer to this question is an ineffective PPE program, which fails to identify hazards and/or improperly assigns adequate personal protection. Applying the PPE Standard to your workplace requires more than selecting and providing equipment. Instead, the OSHA PPE standard is a system of mutually supporting actions, each of which must be in place to ensure full protection of workers. If you’re missing critical elements in your PPE program, you could have serious inadequacies and increased worker injuries. Check out the following areas to ensure your PPE program is functioning effectively.Hazard Assessment and PPE

To create a comprehensive PPE program, employers must evaluate the workplace and job duty hazards. This is the first and most critical step. If you miss hazards or unsafe conditions, you won’t select the proper PPE and workers will be exposed without protection. This is not optional. Hazard assessment is required by OSHA under 1910.132(d)(1), which mandates employers determine present or potentially unsafe conditions which may merit PPE. The assessment should be thorough and include a survey of physical and health hazards. And you should consider work environment, as well as specific job duties or tasks. Examples of hazards include:- Sharp objects which might pierce the feet or cut hands.

- Rolling or pinching objects which could crush hands or feet.

- Electrical hazards.

- Dust, particulates, flying objects, the potential for objects to strike the worker.

- Hazardous radiation (welding, brazing, cutting, furnaces, heat treating, high-intensity lights, etc.)

- Falling objects or potential for dropping objects.

- Potential sources of impact or motion, such as machinery or processes where any movement of tools, machine elements, or particles could exist.

- High temperatures that could result in burns, eye injury, or ignition of protective equipment, etc.

- Chemical exposures.

- Hazardous atmospheres.

- Exposure to blood or other potentially infectious materials. (Covered under the Bloodborne Pathogen Standard, 29 CFR 1910.1030, but employers may identify areas that apply during a hazard assessment.)

- Past performance does not imply future success. In other words, even if workers aren’t getting injured, it doesn’t mean the hazards don’t exist. If your employees have exposure to unprotected hazards, you’re playing Russian Roulette. It’s only a matter of time before someone is injured when exposed to unsafe conditions.

- Frequently overlooked are secondary or seasonal duties workers perform which put them at risk of new or unusual hazards. For example, employers should review annual or semi-annual maintenance tasks. Likewise, look at other tasks that might be nonroutine. Are there additional hazards that may occur?

- What happens when an employee must cover for another worker? Are they provided the correct PPE and training for those duties?

Certification of PPE Hazard Assessment

OSHA takes your PPE hazard assessment very seriously. It must be written and certified to ensure you’ve performed an adequate evaluation. Aside from compliance with the PPE Standard, certification gives you a dedicated process to complete your assessment. According to OSHA, the required workplace hazard assessment must:- Be documented in writing

- Comprehensively identify all hazards or potential hazards

- State name of the person certifying the evaluation

- List the date(s) of the hazard assessment

Training Workers on PPE Use

- Train employees before providing PPE

- Maintain a record of training

- Demonstrate the proper ways to wear all types of required PPE

- Identify various types of PPE and the purpose, as well as levels of protection

- Describe the types of tasks or work environment that pertain to the PPE

Selection of PPE

Do you have workers who grumble about PPE or slack off on wearing the safety equipment? Often, this is because it’s uncomfortable or cumbersome. And if you have a sympathetic supervisor who feels the same and looks the other way, you can have an entire department (or company) that is not wearing the provided PPE, unless management is in the plant. For your PPE program to be successful, employees must wear the required equipment. Improving the comfort and quality of your PPE can often change workers’ mindsets and reduce injuries and incidents almost immediately. If you have workers who aren’t wearing their PPE, ask them why. And then spend some time brainstorming to solve the issue. There are so many varieties of every kind of PPE, it’s likely you’ll find another selection that is more tolerable for your workers.

Periodic Reviews of the PPE Program

The PPE program should be regularly reviewed to ensure no changes or inadequacies are found. Incident and accident reports can be evaluated to determine areas that may involve PPE failures. For example, if an employee had an eye injury while wearing safety glasses, could safety goggles have changed the outcome? You can also use your 300 Logs to look for trending injury events which may indicate PPE needs to be improved or changed for various departments or job duties. (It is also possible that employees need to be retrained on the requirements, too.) But remember, your PPE program should be proactive to be most effective. Don’t wait for accidents and injuries to evaluate it. Frequently review job duties and the environment to look for new potential hazards. [optin-monster slug="zuzuvyij6mtvscihsoql"]Conclusion: PPE--A Good Idea Even Without OHS Regs

We hope this article gave you a better appreciation of the importance and value of PPE and some associated safety issues. For more information about the proper use of PPE, you might also be interested in our article on the hierarchy of control, which includes PPE. Feel free to download the free JHA Guide below, too.

Job Hazard Analysis Guide

Learn how to perform a job hazard analysis on the job with our free step-by-step guide.

Download Free GuideExplore our software solutions designed to help your organization succeed

Request a Demo