April 8, 2020 7 min read

What Is Kanban in Lean Manufacturing?

Industry:

Solution:

In our continuing introduction to lean manufacturing, in this article we are going to introduce kanban, a method used for visual management in lean.

We’ll explain what kanban is, explain its origins, list and explain four principles of kanban and six practices of kanban, introduce the kanban board, and explain some benefits of kanban.

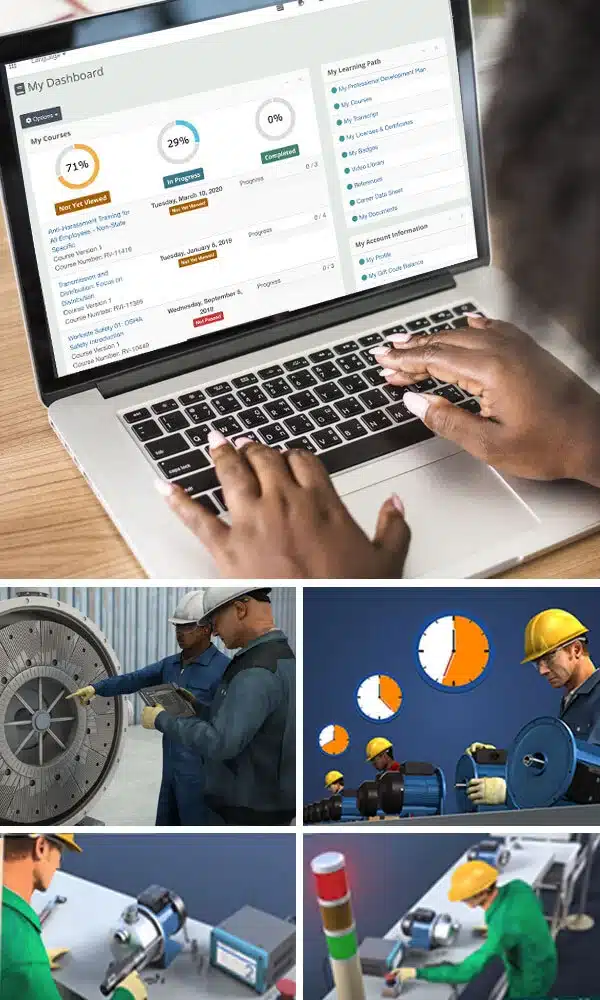

Vector EHS Management Software empowers organizations – from global leaders to local businesses – to improve workplace safety and comply with environmental, health, and safety regulations.

Learn more about how our software can save you valuable time and effort in recording, tracking, and analyzing your EHS activities.

Learn more about how we can help:

- Incident Management Software →

- EHS Inspection Software →

- Key Safety Metrics Dashboard →

- Learning Management System (LMS) and Online Training Courses →

- Mobile Risk Communication Platform

Download our EHS Management Software Buyer’s Guide.

What Is Kanban?

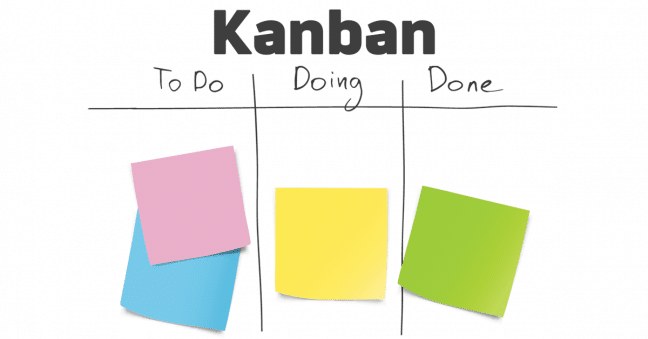

In the simplest terms, Kanban is a way to visually manage the work flow at an organization. Using kanban makes it easier to stay efficient and it helps to quickly identify (and solve) problems in the work flow.

The basic idea of kanban is that the flow of work is represented on a large board with different columns. Work is represented by a card or ticket on the board, and the board is separated into different columns. Each column on the board represents a different phase of the work process, and as the work continues, the card (representing a job) is moved from one column to the next to the next to track progress and eventual completion.

Traditional kanban boards are separated into three columns named something like:

- To do

- Doing

- Done

Different workplaces may use different numbers of columns or use different names for the columns, but the general idea of moving the kanban card from column to column as work is completed remains the same.

In some instances, the board can also include rows, called “swim lanes,” that denote work by different teams.

Traditionally, the kanban method uses something like a bulletin board posted in the work area. That’s still true today sometimes, but today there is often software to manage kanban and to create kanban boards online.

The Origins of Kanban

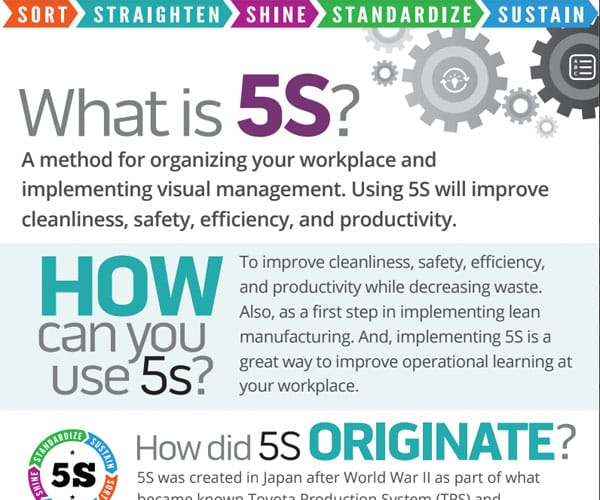

Kanban originated with the Toyota Production System (TPS) and lean manufacturing.

Toyota’s production system was based on a pull system, not a push system. This means their production was based on the “pull” created by consumer demand, not the “push” of production planning to create inventory. The desire to create a push system created what is known as “just-in-time” manufacturing, in which a product was created as close as possible to the time a consumer wanted it (and not sitting in a warehouse). Likewise, as a product was being assembled, downstream processes “pulled” the product further through the production process, and upstream processing areas endeavored to get materials to their downstream counterparts just in time.

Kanban, with its practice of visually mapping progress through production phases, was a helpful way to visually manage workflow in a workplace that emphasized pull and just-in-time.

Kanban went on to be a standard part of the lean manufacturing tool kit and to be used by many manufacturing companies. However, it’s not just for manufacturing, and in fact was picked up by the software industry for agile development.

Four Principles of Kanban

Kanban has four principles. These are:

- Start with what you do now

- Pursue incremental, evolutionary change

- Respect the existing process, roles, and responsibilities

- Encourage acts of leadership at all levels

Let’s look at each in a little more detail:

Start with what you do now

When you’re implementing kanban, don’t change your production processes at the same time. Instead, use kanban to visually manage what you’re doing now.

This way, you’ll avoid creating culture shock and risk losing buy-in at work. Plus, using kanban with your existing processes will help you identify areas for improvement.

Pursue incremental, evolutionary change

Once you’ve implemented kanban, use it to make a series of small changes in a question for continuous improvement.

This matches the typical emphasis of lean on small, incremental improvements, as illustrated in kaizen as well.

Respect the existing processes, roles, and responsibilities

Remember to see that the processes, roles, and responsibilities that exist currently exist for a reason and have value. In general, they’re worth keeping. You’re not prohibited from making change, but you also shouldn’t embrace change for change’s sake or make wild, sweeping, radical changes.

Encourage acts of leadership at all levels

People often mistakenly believe that leadership comes only from “above” in the organizational hierarchy. But to really create a culture of organizational learning and continuous improvement, employees at all levels must adopt kanban and the process of making increment changes for continuous improvement, and in many cases employees will be doing the leading.

Six Practices of Kanban

To make kanban work, follow these six practices:

- Visualize your workflow using kanban

- Limit the work in progress

- Manage the workflow to reduce bottlenecks and create flow

- Define and share work policies explicitly

- Use feedback loops to ease information flow, learn continually, and improve processes and your product (value for customers)

- Be collaborative and experimental to always push for improvement

Let’s look at each a little more.

Visualize your workflow using kanban

Kanban helps you visualize your workflow. This will help you better understand it, in general, but it will also help you better identify problems such as bottlenecks and other inefficiencies as you continue to use kanban at work. In this sense, helping you visualize and improve your work processes, kanban has something in common with value stream mapping.

Once you’ve developed that understanding, you can more productively create improvements.

In kanban, visualization of the work process(es) occurs on the kanban board. Cards represent work items, and columns represent different steps in the workflow. You move the card from column to column as a work item moves from step to step.

One thing that’s important to remember is that the kanban board should be visible to all workers, not just managers and supervisors. Don’t squirrel away your kanban board in your office; put it in the production area so all can see, be updated, and learn together.

Limit the work in progress

Don’t try to push too much work through the system at once, don’t switch teams on and off projects mid-stream, and don’t expect workers to multi-task. Limit the number of active items being worked on (and represented on the kanban board) to a manageable, reasonable level.

Remember, your goal is a “pull” system, with customer demand driving production through the phases.

Consider setting a maximum number of kanban cards (and therefore work items) for each stage and only allowing cards to be pulled into the next stage when there’s capacity in that second stage.

Manage the workflow to reduce bottlenecks and create flow

The whole idea of implementing a Kanban system is to create a smooth healthy flow. By flow, we mean the movement of work items through the production process. We are interested in the speed and the smoothness of movement.

So, managing the flow is about managing the work but not the people. So instead of micro-managing people and trying to keep them busy all the time, we should focus on managing the work processes and understanding how to get that work through the system faster.

Ideally, we want fast and smooth flow. This would mean that our system is creating value quickly. This way we can minimize the average cycle time for production and avoiding the cost of delay but in a predictable fashion.

Define and share work policies explicitly

Nobody in your company–you, managers, supervisors, or workers–can improve your work processes if you don’t understand them. Likewise, kanban can’t be used effective for your continuous improvement efforts if there’s not a single, shared understanding of work processes and how they’re represented on a kanban board.

Be sure to create and share documentation of your work processes and make sure all employees understand them and understand how they’re represented on the kanban board.

And make sure everyone knows the ultimate goal that you’re headed for (creating more value for the customer and decreasing waste) so everyone’s rowing the boat in the same direction.

Use feedback loops to ease information flow, learn continually, and improve processes and your product (value for customers)

The free flow of information, knowledge sharing, and organizational learning are all key aspects of lean manufacturing. That’s true in the kanban method as well.

One way to facilitate that exchange of information, in particular from workers to managers and supervisors, is to have recurrent team meetings in which supervisors ask employees about and study normal work or work as performed. That can include talking about what people did the previous day and what they’ll do today.

These meetings don’t have to be long, but they should happen on a regular basis and employees should see evidence that their input is valued and their insights are implemented. Having meetings like these and never implementing new ideas will kill buy-in from employees quickly.

Read our articles on Learning Organizations, Becoming a Learning Organization, Using Learning Teams at Work, and Psychological Safety and Learning Organizations to learn more about this.

Be collaborative and experimental to always push for improvement

Remember, kanban and lean work through collaboration and experimentation.

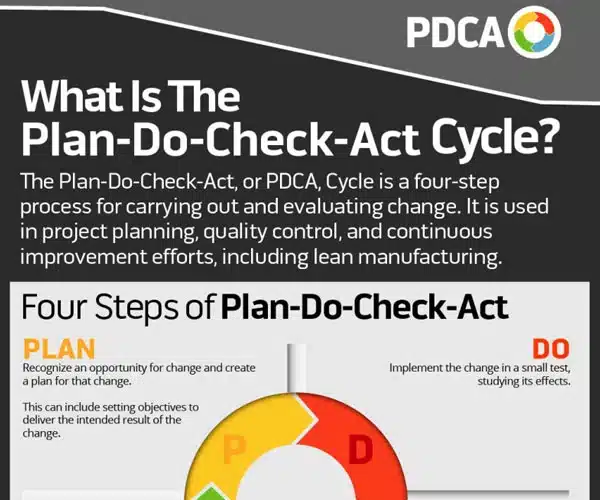

Everyone at your organization needs to know your business goals; understand work, the work flow, and work processes; and must all be continually engaged in a culture of learning and experimentation (with verification, such as through the PDCA Cycle) with the ultimate goal of continuous improvement.

Conclusion: Kanban is an Essential & Helpful Lean Tool

Kanban is an important part of lean manufacturing, and it can also be used even if your organization hasn’t adopted lean. We hope this introduction to kanban has been helpful to you and we wish you luck on your lean manufacturing and/or process improvement journey.

Please feel free to download our free PDCA Cycle infographic below before you go.

Plan-Do-Check-Act (PDCA) Infographic

Problem-solving & continuous improvement tool from lean.

Yes! I Want this Infographic!