October 24, 2024 6 min read

The Rise of Artificial Intelligence in the Manufacturing Industry

Industry:

Solution:

The manufacturing industry is undergoing a significant transformation, and one of the driving forces behind this change is the integration of Artificial Intelligence (AI). Organizations are rapidly embracing AI technologies to streamline operations, enhance product quality, and increase efficiency. Understanding how AI can impact the manufacturing landscape is crucial to stay competitive. In this blog, we’ll explore the role of artificial intelligence in the manufacturing industry, benefits of AI in manufacturing, and resources for adapting to these innovative technologies.

Importance of Artificial Intelligence in Manufacturing Industry

As manufacturers face increasing pressure to reduce costs and improve quality, AI technologies are emerging as essential tools to meet these challenges. AI is revolutionizing the manufacturing industry by:

- Driving efficiency

- Enhancing productivity

- Fostering innovation

The integration of AI in the manufacturing industry is not just a trend; it is a necessity for organizations seeking to thrive in an increasingly competitive landscape. By embracing these emerging technologies, manufacturers can improve operational efficiency, enhance product quality, and foster innovation, ultimately leading to greater profitability and success in the marketplace.

How is AI Used in the Manufacturing Industry?

According to a Deloitte survey, manufacturing stands out as the foremost industry in terms of data generation. Manufacturers must adopt AI to analyze this huge amount of data generated in the sector.

Some prominent AI technologies that are currently being used include:

- Machine Learning. Machine learning analyzes data to optimize processes, improve product quality, and predict outcomes, becoming smarter over time.

- Computer Vision. AI-powered computer vision inspects products, detects defects in real-time, and enhances quality control on the assembly line.

- Predictive Analytics. Predictive analytics forecasts demand and maintenance needs, helping manufacturers prevent downtime and disruptions.

- Robotic Process Automation (RPA). AI-driven robotics automate repetitive tasks, increasing precision, speed, and productivity while reducing human error.

- Natural Language Processing (NLP). NLP allows AI to analyze human language in text or voice, providing insights from unstructured data like maintenance reports and feedback.

- Digital Twins. Digital twins create virtual replicas of production environments, enabling manufacturers to test changes and optimize processes.

- Supply Chain Optimization. AI optimizes supply chains by predicting disruptions, managing inventory, and ensuring timely delivery, improving overall efficiency.

How can AI Improve Workplace Safety?

Talk of AI is everywhere. But what does AI mean when it comes to managing your safety data and the safety of your workforce? Discover practices for assessing the risk and benefits of using AI tools for safety.

Watch Webinar

Benefits of AI in Manufacturing

As artificial intelligence continues to evolve, its applications in the manufacturing sector are transforming traditional processes. By integrating AI, manufacturers are achieving greater productivity, improved quality, and safer work environments.

“83% of companies think AI has made or will make a practical and visible impact.”

– Deloitte

Here are some of the key benefits of AI in manufacturing, revolutionizing how we approach manufacturing operations:

- Increased Efficiency: AI-driven systems streamline production processes, reducing time and energy required for tasks, which leads to faster turnaround times.

- Predictive Maintenance: AI-powered tools can predict machinery failures before they happen, minimizing downtime and costly repairs by scheduling maintenance proactively.

- Smart Quality Control: With AI, manufacturers can enhance quality control by identifying defects and anomalies in real-time, ensuring consistent product standards.

- Cost Reduction: AI optimizes resource use, reducing waste and operational costs while maintaining high production levels.

- Enhanced Safety: AI-driven automation can take over hazardous tasks, improving workplace safety by reducing the risk of accidents for human workers.

- Enhance Productivity: With AI-driven automation, manufacturing employees save time on repetitive work, allowing them to focus on more creative tasks, increasing job satisfaction, and unlocking employees’ full potential.

- Generative Design: By leveraging AI algorithms to generate a wide range of design possibilities, manufacturers benefit from gaining access to innovative designs, improved efficiency, and reduced material waste.

- Data-Driven Decision Making: By analyzing vast amounts of data, AI provides actionable insights that help manufacturers make informed decisions, optimizing processes and strategies.

What is the Future of AI in Manufacturing?

AI in the manufacturing market is expected to reach $16.7 billion by 2026, growing at a compound annual growth rate (CAGR) of 44.3% from 2019.

Additionally, according to a study by PWC, it’s projected that AI will contribute up to $15.7 trillion to the global economy by 2030, with significant portions of that growth stemming from advancements in manufacturing.

These statistics highlight the transformative potential of AI in manufacturing, underscoring its critical role in shaping the industry’s future. As companies invest in AI technologies, they will increasingly rely on these solutions to automate routine tasks, make data-driven decisions, and adapt to changing market conditions. This shift will not only enhance operational efficiencies but also enable manufacturers to respond rapidly to consumer demands, fostering a more agile and competitive landscape.

Will Manufacturing Jobs Be Replaced by AI?

While artificial intelligence in the manufacturing industry efforts is rapidly accelerating, AI is unlikely to fully replace human workers.

Instead, AI will augment human capabilities, allowing workers to focus on more complex and strategic or different tasks. Many manufacturing roles will evolve, requiring employees to collaborate with AI systems to enhance productivity and innovation.

A World Economic Forum report suggests that by 2025, AI and automation could lead to the creation of 97 million new jobs globally. These new roles will require a workforce skilled in technology and data analysis, emphasizing the need for ongoing training and development within the industry.

Furthermore, AI’s ability to analyze vast amounts of data will enable manufacturers to make informed decisions that enhance safety, improve working conditions, and increase overall job satisfaction. As such, AI is not seen as a replacement for human workers but rather as a powerful tool to empower them and drive industry growth.

How Vector Solutions Helps Manufacturers Embrace Digital Transformation

“This LMS has become a game changer for us to train and test our staff at every level of our organization.”

– Manufacturing Training Manager

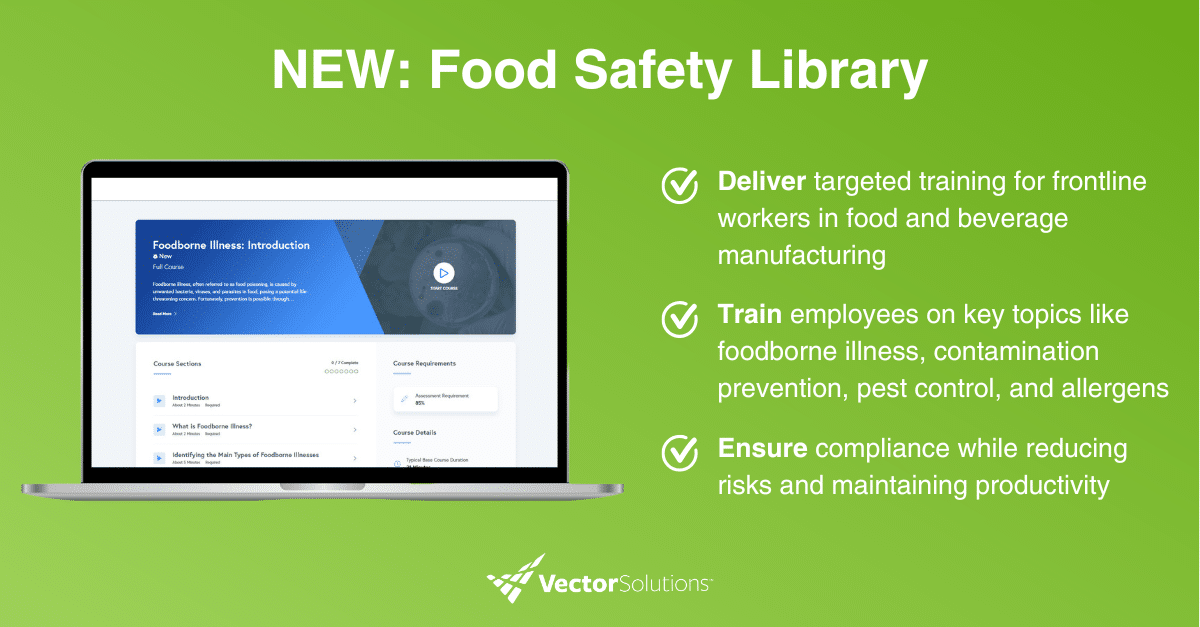

As artificial intelligence continues to shape the future of manufacturing, it’s important to educate your workforce on the latest trends and technologies. Vector Solutions is a leading provider of cutting-edge Learning Management and online training solutions, designed to support organizations as they evolve and adapt to a rapidly changing industry. Our robust catalog of online courses covers many aspects of manufacturing technology and digital transformation. Some featured courses include:

- Digital Transformation: Five Challenges Organizations Face by Not Embracing Technology

- Digital Transformation: What is the Internet of Things?

Ready to learn more? Request a demo today.