Yankee Hoods and Air Systems

Together, the Yankee dryer and Yankee hoods provide the final drying of a tissue sheet before it is wound up by the reel. Some of the drying energy is provided by steam condensing inside the dryer, and the rest is provided by hot air being blown onto the sheet by the Yankee hoods. This module describes the equipment and processes responsible for supplying dry, heated air to, and removing humid exhaust air, from the Yankee hoods on a typical, modern Yankee dryer.

Request a demoCourse Details

Learning Objectives

• Design of Yankee hoods

• Yankee hood air system equipment and flows

• Cross-machine moisture profiling in hoods

• Supply, recirculation, and exhaust air flows

• Heat recovery

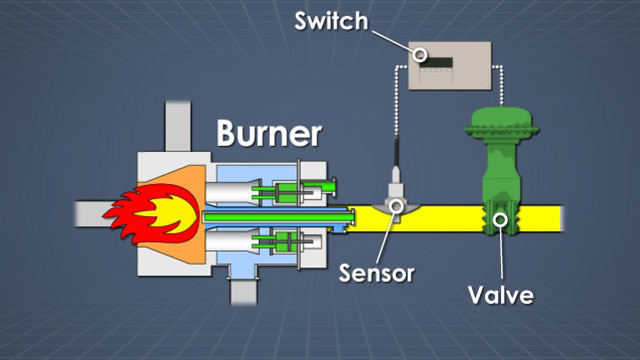

• Gas burner modes, permissives and interlocks

• Why it is important to “balance” the hoods

Specs

| Course Level | Intermediate |

| Languages | English |

| Compatibility | Audio, Video |

| Based on: | Industry Standards and Best Practices |

Key Questions

What is the purpose of the Yankee hoods?

Hoods help dry the sheet by directing hot, dry air onto the sheet. The hoods also removes the humid air that contains the water evaporated from the sheet.

What are the components of the hood system?

The hood and air system includes supply and exhaust fans, gas burners, ducts, heat exchangers, profiling dampers, and blowboxes.

What are the possible air system configurations?

The air system can be parallel, cascade, or mono. A system may be have crossover ducts so it is capable of changing configurations.

What is the purpose of profiling dampers?

The profiling dampers can vary the air flow from the supply header to control the moisture profile across the dryer.

What happens with exhaust air from the hoods?

The hood exhaust air is used to heat the incoming make-up air and sometimes it can also heat water or machine room air.

Sample Video Transcript

In most Yankee hood air systems, the air supply fans pull in fresh preheated makeup air, combine it with some of the still hot recirculated exhaust air and the resulting mixture flows to gas burners. The gas burners directly heat the supply air to the desired temperature. Each supply fan blows this heated supply air through the supply duct and into the hood via an articulating flexible joint. Inside each hood, a supply header extends across the machine and profiling dampers are often installed to vary the airflows across the machine. The hot supply air flows through the supply header and profiling dampers and into a single plenum nozzle blow box or multiple cross nozzle blow boxes. The blow box or blow boxes direct the hot air out through holes or nozzles and down onto the sheet surface. Note that the supply fan speed controls the airflow to each hood, and therefore, the velocity of the air impinging on the sheet, commonly referred to as the air impingement velocity.

Demos + Pricing

Learn more about our courses, get pricing, and see our platform.