Yankee Dryer Design and Construction

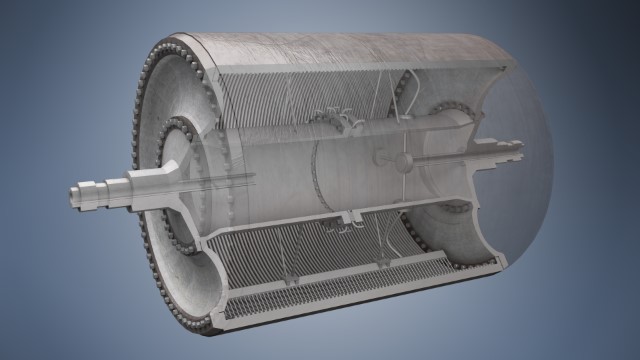

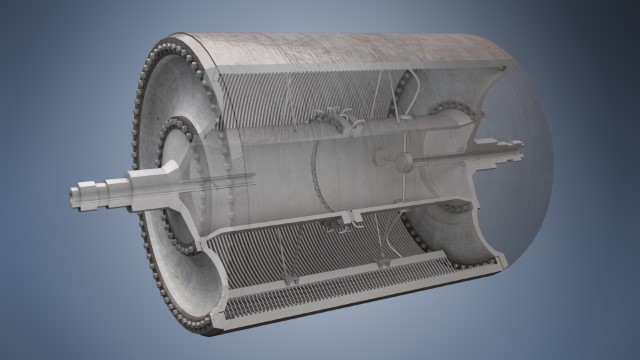

The Yankee dryer is a large, steam-heated, pressure vessel that is used in the production of tissue grades. Two critical operations occur at the Yankee – the sheet is dried to its final moisture target, and it is creped to add bulk, stretch, and softness to the sheet. The design and construction of Yankee dryers has evolved over time to optimize these two operations and also provide a safe work environment for the people who work around them. This course describes the major external and internal components of a Yankee dryer installed on a tissue machine, and the purpose or function of each component.

Request a demoCourse Details

Learning Objectives

• The major external and internal components of a Yankee dryer

• The purpose or function of each component

• The importance and impact of the Yankee crown and shell thickness

Specs

| Course Level | Intermediate |

| Languages | English |

| Compatibility | Audio, Video |

| Based on: | Industry Standards and Best Practices |

Key Questions

What is the purpose of the Yankee dryer?

A Yankee dryer dries the tissue sheet to its final moisture with help from hot air hoods. The Yankee also provides a surface for creping.

What Yankee design parameters affect sheet drying?

The shell diameter, shell thickness, and the heat transfer ability of the shell material all impact sheet drying.

Why is a Yankee crowned?

The Yankee is crowned to compensate for internal steam pressure, external loads of the pressure roll and doctor blade, and temperature differences across the dryer. The crown on the Yankee and pressure roll are designed to produce a uniform nip load across the width of the machine.

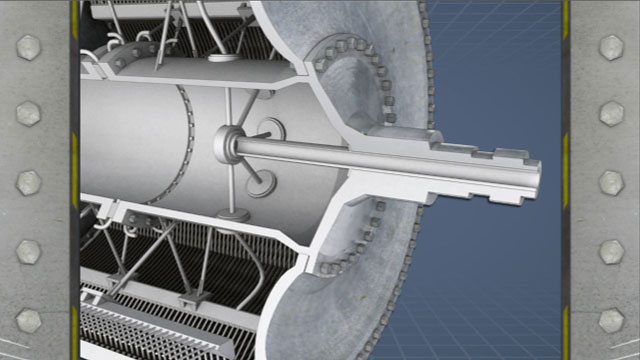

What is a rotary joint?

A rotary joint is the connection point between the rotating dryer and the external, stationary steam and condensate piping.

How is condensate removed from the dryer?

This pipes called soda straws extend from condensate headers into grooves on the inside of the dryer shell. Condensate flows up the straws and into the header and then riser pipes transfer the condensate to a central collection pipe that removes it from the dryer.

Sample Video Transcript

The major components of a Yankee dryer include the shell, heads, bearings, journals, steam and rotary joints, steam distribution pipes, center stay, grooves and ribs, soda straws, condensate headers, riser pipes, and the central steam collecting pipe. These components must be designed to provide methods for introducing steam to the inside of the Yankee, transferring heat to the sheet on the Yankee surface, and removing the condensate that forms. The design and operation of all of the major components will be described in this module.

Course Applies To

Demos + Pricing

Learn more about our courses, get pricing, and see our platform.