Yankee Dryer Coating

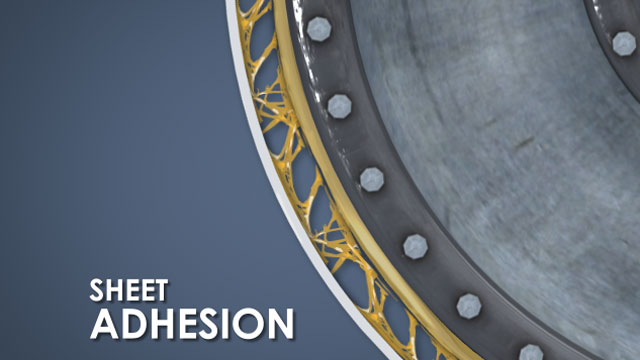

The Yankee dryer is a large, steam-heated, pressure vessel that is used in the production of tissue grades. Two critical operations occur at the Yankee dryer: the sheet of tissue is dried to its final moisture target, and it is creped by the creping doctor. It is the creping process which is responsible for the bulk, stretch, and softness that are desirable in tissue grades. Coating chemicals are sprayed directly onto the dryer surface after the sheet has been removed by the creping doctor. The purpose of the coating is to hold or stick the sheet to the Yankee. This affects drying because sheet adhesion affects heat transfer from the Yankee dryer shell to the sheet, and it affects creping because it affects how the sheet releases from the dryer at the creping doctor. A uniform, pliable coating produces a high quality sheet with uniform crepe, while it protects both the dryer surface and the creping doctor blade from excessive wear.

Request a demoCourse Details

Learning Objectives

• The purpose of the Yankee dryer coating

• How the coating affects the drying and creping processes

• Common Yankee dryer coating ingredients

• Yankee coating application

Specs

| Course Level | Intermediate |

| Languages | English |

| Compatibility | Audio, Video |

| Based on: | Industry Standards and Best Practices |

Key Questions

What are the components of Yankee dryer coatings?

Adhesives, release agents, and modifiers are the three main classes of coating chemicals.

What are adhesives?

Adhesives are poylmers that cross-link on the dryer and provide the base adhesion to stick and hold the sheet to the dryer surface.

What are modifiers?

Modifiers added to the coating formulation to change some aspect of the adhesion. They can be used to increase the adhesion, soften the coating, improve the re-wettability of the coating, or control the amount of coating that builds on the dryer. Polyvinyl alcohol (PVOH) is a common modifier.

How is the coating applied?

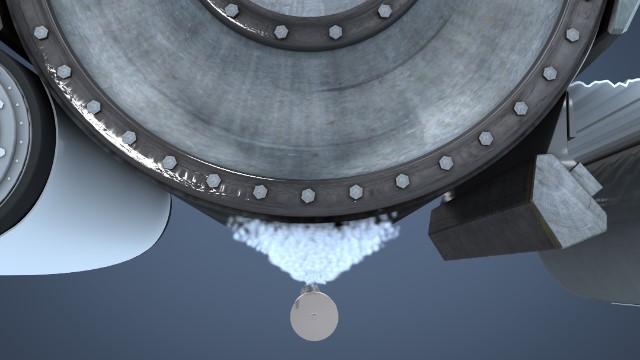

A sprayboom under the Yankee dryer between the cleaning doctor and pressure roll sprays the coating mixture onto the dryer surface.

What are some indications of coating problems?

Coating problems can cause streaks or bare spots on the Yankee surface, uneven reel build, uneven creping blade wear, sheet wrinkling, uneven draws, or loose/tight sheet edges.

Sample Video Transcript

Coating chemicals are sprayed directly onto the dryer surface by the Yankee Sprayboom after the Creping Doctor. The purpose of the coating is to hold or stick the sheet to the Yankee in order to ensure uniform crepe, uniform drying, and overall high sheet quality. The creping blade removes the sheet from the dryer’s surface, but the point of separation is actually under the sheet, in the layer of coating. This brings up two important points, first that the creping blade does not contact the drier surface, rather it rides in the coating. Because the creping blade is usually made of a material that is much harder than the Yankee dryer, this prevents severe wear of the dryer. Secondly, not all of the coating is removed by the creping blade. Some coating remains on the dryer surface at all times.

Course Applies To

Demos + Pricing

Learn more about our courses, get pricing, and see our platform.