Valve Performance

The right valve type and size must be used to ensure it works properly and maintains the desired setpoint within an acceptable range. This course covers several design properties that determine valve performance, including the valve coefficient, flow characteristic, pressure class, and rangeability.

Request a demoCourse Details

Learning Objectives

By the end of this course, you will be able to:

- Describe valve coefficient

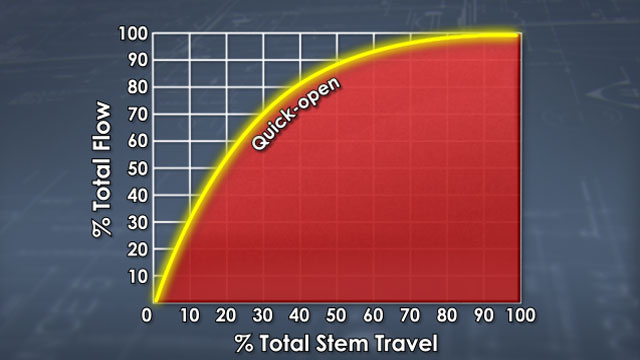

- Differentiate between linear, equal percentage, and quick-open flow characteristics

- Describe how valve stroke affects flow characteristics

- Differentiate between inherent and installed flow characteristics

- Describe pressure and shutoff classes

- Differentiate between feedback and feedforward control loops

- Describe rangeability

Specs

| Course Level | Intermediate |

| Languages | English, Portuguese |

| Compatibility | Audio, Video, MobileReady, Responsive |

| Based on: | Industry Standards and Best Practices |

Key Questions

What is the valve coefficient?

The valve coefficient is a measure of how much fluid can flow through a valve in a given time period.

What is the valve stroke?

The valve stroke is the distance the stem must move to go from fully closed to fully open.

What is the flow characteristic?

The flow characteristic describes the relationship between the stem’s movement through its stroke and the corresponding changes to the valve’s flow rate.

What are valve pressure classes?

Every valve can handle a certain amount of internal pressure. This is the valve’s pressure rating. Valves can be classified by how much pressure they can handle. The most commonly used standards for valve pressure classes are set by the American National Standards Institute (ANSI). There are six standard pressure classes and additional special classifications and intermediate classifications.

What are valve shutoff classes?

Valves are also rated by the amount of leakage they permit when sealed. This leakage is measured as a percentage of the valve’s rated flow capacity. ANSI has created six shutoff classes, with Class I being the weakest seal and Class VI the strongest.

What are actuator-controlled valves?

Valves that are not controlled by a manual operator, such as a lever or handwheel. Instead, actuator-controlled valves are controlled by an automatic actuator. Automatic actuators are frequently a part of a control loop that also includes a sensor and a controller.

What are control loops?

In a feedback control loop, the sensor monitors downstream conditions and sends that information to the controller. This then controls the valve. There are feedforward and feedback control loops.

Whtat is rangeability?

Rangeability is a measure of how effectively an automatic control valve can control a flow after receiving a signal from the controller. It is defined as the ratio of the maximum controllable flow divided by the minimum controllable flow through a valve.

Sample Video Transcript

It is important to properly match the valve coefficient to a valve’s intended use in a system. If the valve coefficient is too small, not enough fluid will pass through the valve and upstream equipment, such as pumps, can be damaged. If the valve coefficient is too large, the following problems could occur. The valve may be more expensive, larger, or heavier than necessary. The valve or pipes may be damaged as a result of too much flow, or the valve may experience the “bathtub stopper” effect. This occurs when the valve is near its closed position and is rapidly sucked closed, sending damaging waves through the system.

Additional Resources

- Valve Manufacturers Association of America – www.vma.org

- VMA Common Valve Types – www.vma.org/?CommonValveTypes

- Werner Solken Explore the World of Piping – www.wermac.org

- Introduction to Valves http://www.wermac.org/valves/valves_general.html

- United Valve – www.unitedvalve.com

- http://unitedvalve.com/industry-information/valve-standards/

Course Applies To

Demos + Pricing

Learn more about our courses, get pricing, and see our platform.