Tissue Making Basics

Modern tissue making is a complicated process. There are many steps involved in the production of tissue from wood. This course begins with a description of how the pulping process turns wood chips into pulp. It ends with an explanation of how consumer-ready tissue products are prepared for shipment to customers in the converting area.

Request a demoCourse Details

Learning Objectives

• The basic papermaking process

• The role of hardwood and softwood fibers in papermaking

• How tissue is produced on a tissue machine

• Definitions for consistency and creping

• The major sections and processes of a tissue machine

• Equipment and processes in the thick stock, thin stock, and white water systems

• Equipment and processes used to convert tissue into consumer-ready products

Specs

| Course Level | Intermediate |

| Languages | English |

| Compatibility | Audio, Video |

| Based on: | Industry Standards and Best Practices |

Key Questions

What are the common sections of a tissue machine?

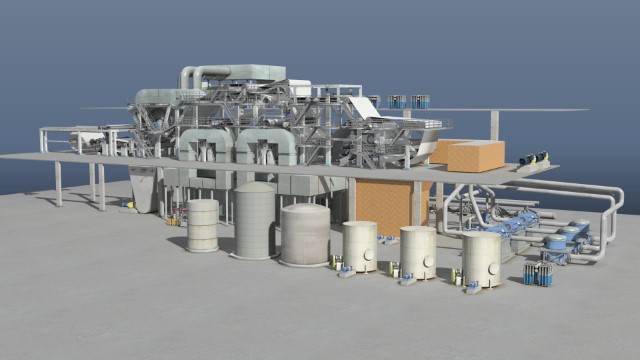

A tissue machine can include a former, press or through-air dryer, Yankee dryer, and a reel. Sometimes a calender is used to produce a uniform sheet thickness.

What is a through-air dryer?

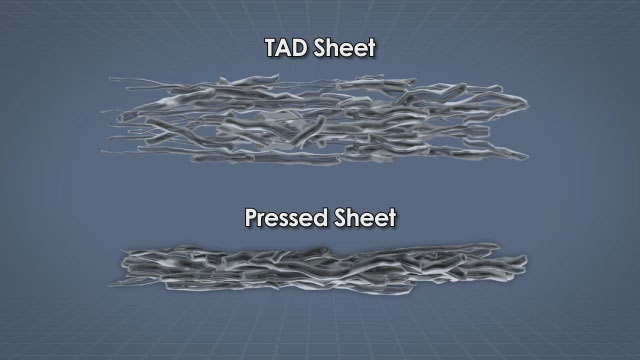

A through-air dryer, or TAD, is a large perforated roll that is often used on tissue machines to replace the press section. Hot air is used to dry the sheet. A TAD can produce a bulky sheet because it is not pressed.

What Is a Yankee dryer?

The Yankee dryer is a large, steam-heated cylinder which is used to dry the sheet and provide a surface for creping tissue. A coating is applied to adhere the sheet to the Yankee to help drying and creping.

What is creping?

A blade is used to remove the sheet from the Yankee dryer. The sheet crashes into the blade. This collision breaks up fiber bonds, so a softer, bulkier sheet is formed.

How are parent rolls converted to tissue products?

Parent rolls are unwound. While unwinding, the sheet can be printed, embossed, or combined with additional sheets. The sheet is perforated and wound onto cardboard tubes to form a log. The logs are cut into individual rolls by log saws, then wrapped and/or bundled and put into cases.

Sample Video Transcript

The papermaking process was first patented in China over 1900 years ago. While the raw materials and technologies have evolved over time and become increasingly complex, the basic process has remained the same. Whether paper is made by hand, sheet by sheet, or on a paper machine at a speed of 80 miles per hour, it includes these three basic steps: one, create a solution of water and cellulose fibers from plants, two, strain the solution so that the fibers form a sheet, and three, dry the sheet.

Course Applies To

Demos + Pricing

Learn more about our courses, get pricing, and see our platform.