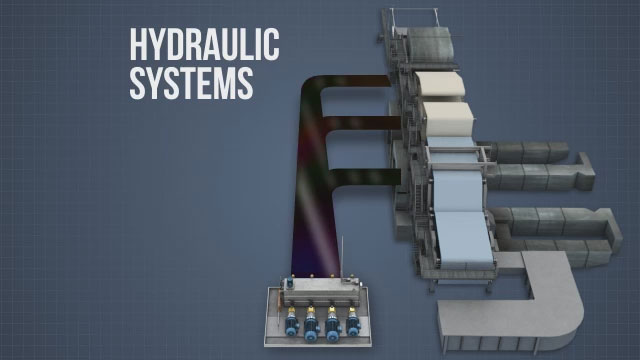

Tissue Machine Hydraulic Systems

Hydraulic systems can be used to load, unload, lift, retract, rotate, and operate many different components. Tissue machines typically employ one or more hydraulic systems, each composed of a fluid reservoir, reservoir heaters, one or more hydraulic pumps, filtration equipment, cooling heat exchanger, distribution and return piping, valves, actuators, and instruments and controls. Strainers, filters, heat exchangers, and sometimes water-removal equipment are used to keep the hydraulic fluid clean and dry, and in the proper temperature range, in order to minimize problems and wear, and successfully operate hydraulically-actuated equipment.

Request a demoCourse Details

Learning Objectives

Explain the purpose of hydraulic systems Identify the safety hazards and safety guidelines associated with hydraulic systems Identify and describe the common components of a typical tissue machine hydraulic system List the functions of common hydraulic system components Describe the types of valves that are commonly used in hydraulic systems Identify and describe the typical process flows of a hydraulic system

Specs

| Course Level | Intermediate |

| Languages | English |

| Compatibility | Audio, Video |

| Based on: | Industry Standards and Best Practices |

Key Questions

What are some of the things that hydraulic systems are used for on tissue machines?

They can be used to deflect variable crown rolls, load/unload pressure rolls, cantilever machine sections, and reposition doctors, steam boxes, rolls, and other equipment, especially at the dry end.

What are some of the safety hazards associated with hydraulic systems?

Burns from hot fluids, bruises and abrasions from unsecured lines or hoses, fires if an ignition source contacts hydraulic fluid, and pinhole leak injections into the skin.

What is the purpose of the “breather assembly” on hydraulic fluid reservoirs?

The breather assembly lets filtered air in and out of the tank as the fluid level changes.

Why is it important to have a relief valve downstream of a hydraulic pump?

Hydraulic pumps are usually positive displacement pumps, which are relatively unaffected by discharge pressure. The relief valve prevents downstream damage from overpressurization.

Why does a hydraulic system have equipment to both heat AND cool the hydraulic fluid?

The heaters keep the fluid warm during shorter shutdowns and startups, while the cooler removes heat from the fluid during machine operation, because the fluid absorbs heat from the process.

Sample Video Transcript

Accumulators are often installed in hydraulic systems to provide stored energy when high loads are required or when hydraulic pressure is suddenly lost, such as when a pump shuts down. They are pressure vessels with pressurized bladders that are used to maintain and control the fluid pressure inside the vessel. Accumulators can be used to maintain hydraulic pressures for short periods of time, dampen pressure pulses in the fluid flow, or allow equipment to slowly return to a lower energy state if hydraulic pressure is lost.

Demos + Pricing

Learn more about our courses, get pricing, and see our platform.