Tissue Machine Forming Fabric Design

Tissue machine forming fabrics are designed to retain as much fiber and other furnish components as possible while allowing water to drain through them as quickly as possible. These fabrics are typically produced from monofilament strands or yarns that are woven together in a pattern that can be classified by their fabric style (or weave); mesh, count, and diameter; surface topography; and air permeability. This module discusses how each of these characteristics affect final sheet quality.

Request a demoCourse Details

Learning Objectives

• Identify machine direction and cross direction

• List the fabric characteristics that should be considered during forming fabric selection

• Describe fabric styles (single, double, triple layer)

• Describe mesh, count, and yarn diameter

• Describe surface topography

• Describe air permeability

• Describe how the fabric characteristics impact dewatering and formation of a sheet

Specs

| Course Level | Intermediate |

| Languages | English |

| Compatibility | Audio, Video |

| Based on: | Industry Standards and Best Practices |

Key Questions

What are the two main jobs of a forming fabric?

To retain as much fiber and other furnish components as possible, and to allow water to drain through as quickly as possible.

What are the most common fabric styles or weaves used in forming fabrics?

Double layer fabrics are commonly used, but another style might be chosen based on trial work and experience.

What is the difference between “mesh” and “count”?

Mesh refers to the number of MD yarns per inch of fabric, while count refers to the number of CD yarns per inch of fabric.

Why can’t air permeability (which measures air flow) be used alone to predict the drainage capacity of a fabric?

Because it does not take into account the impact of the fibers and furnish on drainage. Surface topography and fabric construction both affect furnish retention and so can also affect the dewatering capacity of the fabric.

What four of characteristics must be considered during forming fabric selection?

Weave pattern; mesh, count, and yarn diameter; surface topography; and air permeability must be considered.

Sample Video Transcript

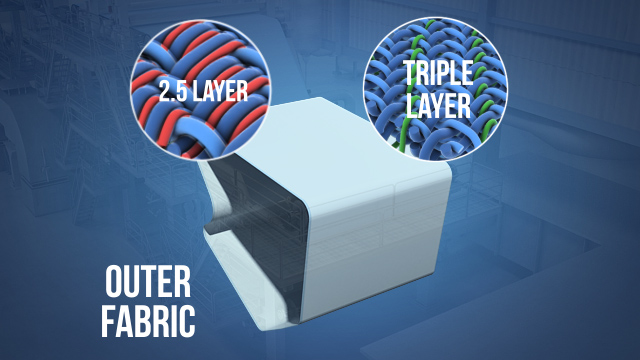

Fabrics are formed by weaving together yarns oriented in the machine direction, MD, and cross direction, CD. There are many different weave patterns, but they can be grouped into four general categories or styles, based on the number of CD yarn layers. The four fabric styles are: single layer, one set of CD yarns woven together with one set of MD yarns. Double layer, two sets of CD yarns stacked on top of each other, woven together with one set of MD yarns. Two-and-a-half layer, additional CD yarns, typically smaller in diameter, added to the top layer of a double layer fabric to provide better fiber support. And triple layer, two single-layer fabrics bound together by a set of smaller CD strands.

Course Applies To

Demos + Pricing

Learn more about our courses, get pricing, and see our platform.