Supported Scaffold Safety

This course covers some of the more important OSHA requirements for supported scaffolds, as well as basic safe practices for working on or near these scaffolds. It is intended as an introductory or refresher course for construction and general industry workers who will be working on or near scaffold systems.

Request a demoCourse Details

Learning Objectives

At the end of this module, you will be able to:

- Identify the main types of supported scaffolds;

- List hazards associated with working on or near scaffolds;

- List four main causes of scaffold injuries;

- List scaffold training requirements;

- List important scaffold safety regulations;

- Identify and describe safe principles of supported scaffold assembly;

- Describe safe work practices on supported scaffolds; and

- Describe fall prevention and protection for working on scaffolds.

Specs

| Course Level | Intermediate |

| Languages | English, French, Spanish |

| Compatibility | Audio, Video |

| Based on: | OSHA 29 CFR 1926.451: Scaffold - General Requirements OSHA 29 CFR 1910.28: Safety Requirements for Scaffolding Industry Best Practices |

Key Questions

What are you required to do if working on surfaces over 10 feet tall?

OSHA requires fall protection for scaffold workers who are working on surfaces that are elevated more than 10 feet.

What are the four most common frame and tube-and-coupler supported scaffold types?

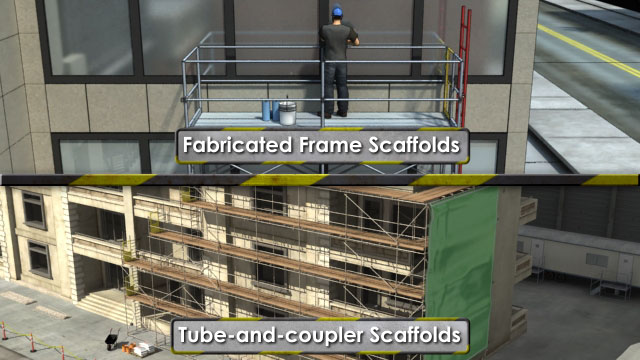

The four main types of supported scaffolds are: fabricated frame scaffolds, tube-and-coupler scaffolds, mobile scaffolds, and pole scaffolds.

What are the main components to scaffold footing?

Base plates and mud sills are the main components and are used to stabilize the scaffold foundation by spreading weight over a greater surface area.

What are the height restrictions for a free-standing scaffold?

The maximum allowable height of a free-standing scaffold is dependent on the width of the base; it cannot exceed four times its base width.

What additional supports must you use if the height of a scaffold cannot be freestanding?

When a scaffold can no longer be free standing due to its height, Guy Wires (wires connected from the scaffold to the ground), as well as Ties and Braces (these connect a scaffold to an adjacent structure, like a building).

What factors must be taken into account when determining load capacity for a scaffold?

The scaffold’s height, material being used, and the amount of cross-bracing must all be factored in.

What are the commonly used scaffold tags used to communicate the status of a scaffold to onsite workers?

The tag system that is commonly used includes: a red tag, which indicates the scaffold shouldn’t be used; a yellow tag, which indicates the scaffold has been modified to meet specific requirements and may be hazardous; and a green tag, which indicates the scaffold is safe and ready to use.

What is the fall protection system OSHA requires if a person is working in an area where they could fall more than 10 feet?

The two types of fall protection required by OSHA are Guardrails and Personal Fall Arrest Systems (PFAs).

How often should the competent person inspect the scaffold and it’s components?

It should be inspected at the following times: daily-before each work shift and after any event that may have created a new hazard.

Sample Video Transcript

Scaffolding can be overloaded by placing too much weight on the structure. Overloading is a common cause of scaffold collapse. In general, a scaffold must be able to support its own weight, plus four times the maximum intended load. The intended load includes people, materials, tools, and any additional components the scaffold will support. Most scaffolding components have a designated load capacity given by the manufacturer. For the most part, components from different scaffold systems should never be mixed and matched. This is especially true of components that are made of different metals, because there can be a chemical reaction between the metals that weakens them. The competent person can decide if components from different systems can be used safely together. There are many other factors that must be taken into account when determining load capacity, including the scaffold height, the material being used, and the amount of cross-bracing. Osha has several tables that give loading rules based on these factors.

Additional Resources

- U.S. Department of Labor’s Occupational Safety & Health Administration (OSHA) – www.osha.gov

- OSHA Safety and Health Topics – https://www.osha.gov/SLTC/scaffolding/index.html

- OSHA eTools – https://www.osha.gov/SLTC/etools/scaffolding/supported/index.html

- OSHA Publications – https://www.osha.gov/Publications/OSHA3150/osha3150.html

- Scaffold & Access Industry Association (SAIA) – www.saiaonline.org

- SAIA Supported Scaffold Council – http://www.saiaonline.org/SupportedScaffold

Course Applies To

Demos + Pricing

Learn more about our courses, get pricing, and see our platform.