Power Boiler Feedwater and Steam

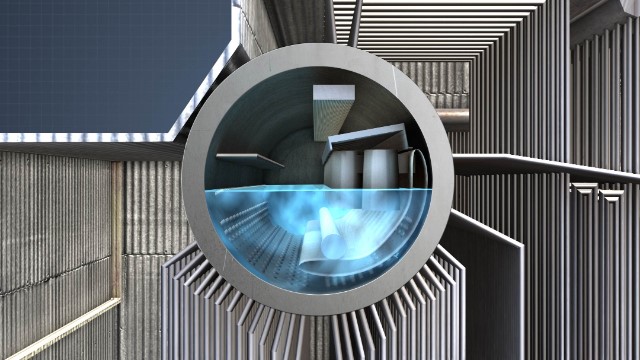

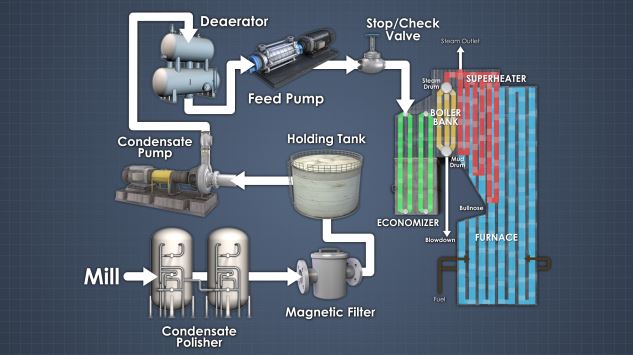

The purpose of a power boiler is to create steam by applying heat energy to water. The water supplied to the boiler, which is converted to steam, is called feedwater. This feedwater system removes any impurities in the condensate, which is steam converted back to water, preheats and pressurizes it then returns it to the power boiler steam drum. The power boiler control system maintains the proper flow of feedwater to the boiler. As the hot combustion gases pass from the furnace through the generating tube bank, steam is formed in the tubes and rises to the steam drum. This module describes the major components and flows associated with feedwater and steam in a power boiler.

Request a demoCourse Details

Learning Objectives

• Define “feedwater” and “latent heat”

• Identify and describe the safety hazards and guidelines associated with power boiler feedwater and steam

• Identify the two typical sources of feedwater in a power boiler

• Identify and describe the major components of a feedwater system

• Explain the flows of condensate and makeup water to the boiler

• Describe the effects of improper feedwater levels in the steam drum

• Identify and describe the major components of a steam system

• Describe the flow of water and steam within a power boiler

Specs

| Course Level | Intermediate |

| Languages | English, Portuguese, French, Polish, Russian |

| Compatibility | Audio, Video |

| Based on: | Industry Standards and Best Practices |

Key Questions

What is feedwater?

The water supplied to the boiler, which is converted to steam, is called feedwater.

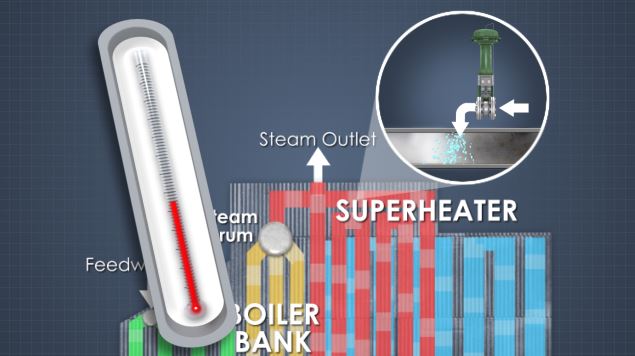

What is latent heat?

Latent heat is the energy released or absorbed by a body or thermodynamic system during a constant temperature process, such as a phase change.

What are the two typical sources of feedwater in a power boiler?

The two sources of feedwater are typically condensate, or condensed steam, returned from other facility processes, and fresh makeup water.

What are the major components of a feedwater system?

Clarifier, sand filters, demineralizer, condensate polisher, condensate pump, deaerator, feed pump, feedwater heater, economizer, and feedwater stop/check valve.

What are the major components of a steam system?

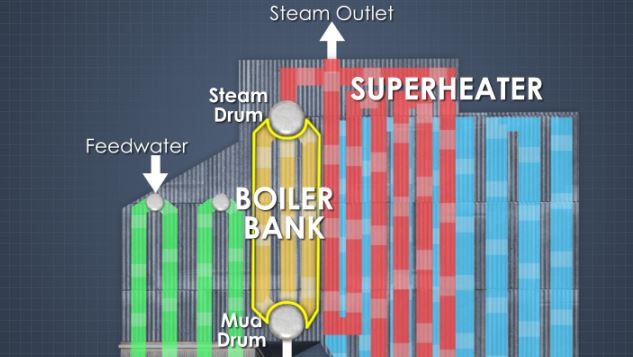

Steam drum, mud drum, generating tube bank, superheater, main steam stop, and the attemporator.

Sample Video Transcript

The purpose of a power boiler is to create steam by applying heat energy to water. The water supply to the boiler, which is converted to steam, is called “feed water”. This feed water system removes any impurities in the condensate, which is steam converted back to water, preheats and pressurizes it, then returns it to the power boiler steam drum. The power boiler control system maintains the proper flow of feed water to the boiler. As the hot combustion gases pass from the furnace through the generating tube bank, steam is formed in the tubes and rises to the steam drum. The steam system is the path that the water entering the boiler steam drum follows until it passes through the main steam stop as high-pressure and temperature steam. The power boiler control system maintains the correct flow of steam at the proper pressure and temperature.

Course Applies To

Demos + Pricing

Learn more about our courses, get pricing, and see our platform.