Multi-Layer Hydraulic Headboxes – Tissue

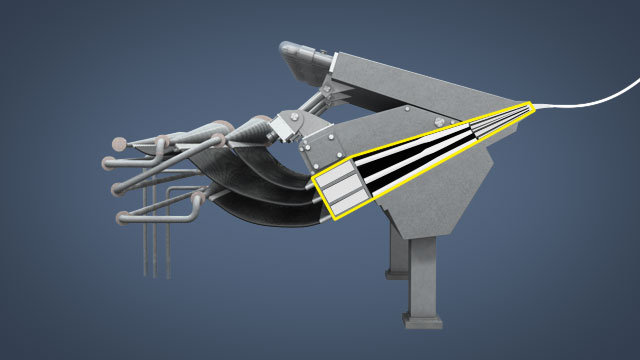

A modern multi-layer hydraulic headbox is designed to deliver a uniform, low consistency stock stream to the forming section of a tissue machine. The stock inlet headers, dilution profiling header, turbulence elements, layering vanes, and headbox movements and adjustments must all be designed to create and maintain turbulence and deliver a well-distributed fiber suspension to the former at the correct angle and location. Proper design, operation, and maintenance are all critical factors in the optimal performance of a tissue machine headbox. Optimal performance of the headbox will produce a sheet with the desired attributes. Understanding how all of the headbox components function and interact will assist in both day-to-day operations and troubleshooting efforts. [course outline] Introduction Headbox Objectives Advantages of a Multi-Layer Headbox Headbox Components Stock Flows to Headbox Stock Inlet Headers Dilution Profiling and Fiber Orientation Dilution Profiling System Recirculation Lines Recirculation Flows Elements Inside th

Request a demoCourse Details

Learning Objectives

• Describe the purpose and objectives of the headbox on a tissue machine

• Describe the advantages of a multi-layer headbox

• Identify and locate the major components of a multi- layer headbox

• Identify stock and recirculation flows

• Describe the available adjustments to the headbox

• Identify protection and care guidelines for the headbox and forming fabrics

Specs

| Course Level | Intermediate |

| Languages | English |

| Compatibility | Audio, Video |

| Based on: | Industry Standards and Best Practices |

Key Questions

What are the advantages of a multi-layer headbox?

Multi-layer headboxes produce a “layered” sheet. The stock blends can be optimized for efficient fiber usage and to achieve the desired sheet properties.

Are the stock approach systems the same for multi-layer headboxes and non-layered headboxes?

No. Because the different layers can have different furnish compositions, each layer has its own stock preparation and delivery system.

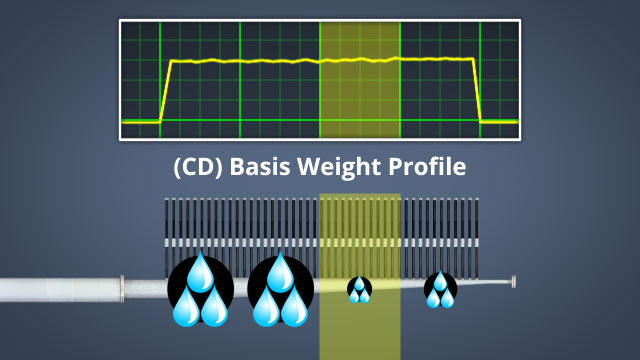

What are the advantages of dilution profiling systems over tradition slice lip micro-adjusters?

Dilution profiling systems eliminate the cross-flows in the stock jet and fiber orientation variability that is caused by slice lip opening adjustments. Headboxes can include both.

What happens when the slice opening is widened slightly?

The pressure inside the headbox initially drops, so the fan pump speeds up to increase the headbox pressure, which increases the total flow through the headbox. The end effect is a drop in the headbox consistency.

Why is the stock jet geometry important?

Sheet formation and quality are greatly affected by jet length, jet angle, and jet impingement.

Sample Video Transcript

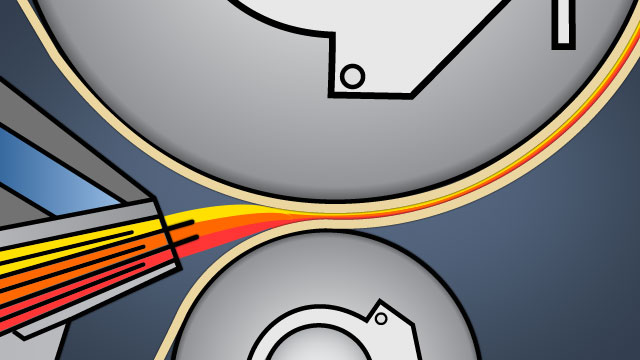

A hydraulic headbox contains several critical components which help it to deliver a uniform dispersed flow of stock across the entire width of the former. These include tapered stock inlet headers equipped with recirculation valves and lines, turbulence elements such as banks of tubes, stilling or equalization chambers, drilled plates, and converging channels created by flexible sheets or veins, layering sheets or veins, the slice lips and slice opening, slice lip micro adjustment, and jet angle and jet length adjustments.

Course Applies To

Demos + Pricing

Learn more about our courses, get pricing, and see our platform.