Belt Drive Adjustment

The primary function of all belt drives is the transmission of power from a source, such as an engine or electric motor, to a variety of devices. Improper tension and misalignment are the main problems that cause belts to fail. Both of these can be prevented with regular inspections, and basic knowledge of how to adjust tension and alignment. This course will describe safety measures for working with belts and drives, how to prevent common belt problems, how to inspect a belt, as well as how to remove and replace belts.

Request a demoCourse Details

Learning Objectives

• List safety measures for working with belts and drives

• Describe how to prevent common belt problems

• List steps for inspecting a belt

• Describe how to measure and adjust belt tension

• Describe how to remove and replace belts

• Describe types of and adjustments for pulley or sheave misalignment

Specs

| Course Level | Intermediate |

| Languages | English |

| Compatibility | Audio, Video |

| Based on: | Industry Standards and Best Practices |

Key Questions

What is a belt drive protector and where can they be found?

Most belt drive systems can be found on the external sides of the powered equipment, so they are often covered with a protective casing. The casing stops foreign objects from interfering with the operation of the belt, stops dirt from building up in the sheaves, and protects nearby team members from the danger of moving parts.

What is the first (important) step to take when performing belt drive maintenance?

When performing belt drive maintenance, one important step that is often forgotten is to perform a close inspection of the belts and of each sheave and its grooves. This inspection should include checking for proper contact between the belts and the sheaves and looking (and feeling) for cracks, chips, or excessive groove wear.

When it’s time, how do you replace the belt on the belt drive system?

To replace the belt. Fit the new belts onto the sheaves. Adjust out one of the sheave pulleys until the belt is sufficiently tensioned. At this point, just use a rough estimate of the required tension.

How do you check the belt tightness after you’ve replaced it?

Belt tightness is checked at the middle distance between sheaves by deflecting one belt with a tensioning tool. The tool should be set to the belt manufacturer’s requirements. A generic check of belts may be done by using 3/16″ defection for each foot of distance between the center of the sheaves. This is a quick check to indicate the need for further service.

Sample Video Transcript

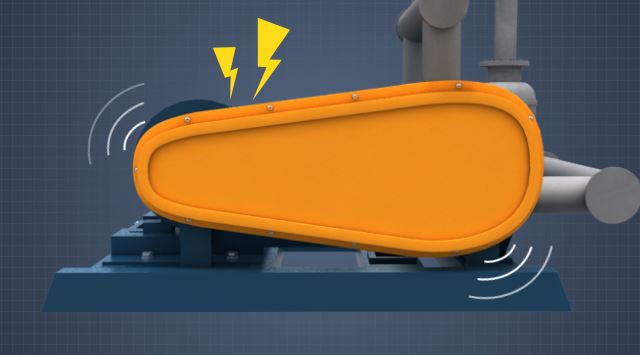

The two main problems that cause belts to fail are improper tension and misalignment. Both of these can be prevented with regular inspections and basic knowledge on how to adjust tension and alignment when needed. A belt that is not properly adjusted will tend to vibrate or jerk. It will also wear out much quicker. Another factor that can damage belts is improper storage and handling. Belts should not be exposed to temperature extremes, high humidity, or sunlight. They should also be kept free of dust, water, oil, grease, or rust.

Course Applies To

Demos + Pricing

Learn more about our courses, get pricing, and see our platform.