Hydrogen Sulfide Awareness

Sometimes what you can’t smell can hurt you, and hydrogen sulfide (H2S) is a prime example of this hidden danger. Protect yourself and your team with our comprehensive Hydrogen Sulfide Awareness Course, including its exposure risks and effects, toxicity, ignition sources, detection methods, and preventive measures. This course also covers proper evacuation procedures to ensure safety in the event of an H2S leak. By understanding these essential aspects, you can significantly reduce the risk of exposure and create a safer working environment.

Request a demoCourse Details

Learning Objectives

- Understand the description of Hydrogen Sulfide (H2S)

- Recognize the exposure risks and toxicity of H2S

- Identify ignition sources of H2S

- Learn detection methods for Hydrogen Sulfide

- Implement prevention strategies for H2S exposure

- Plan and execute evacuation procedures in case of H2S presence

Specs

| Course Level | Intermediate |

| Languages | English |

| Compatibility | Audio, Video |

Key Questions

Hydrogen Sulfide is a colorless gas known for its pungent odor of rotten eggs. It is highly toxic and flammable, and exposure can lead to serious health risks.

Why is Hydrogen Sulfide training important?Hydrogen Sulfide training is crucial because H2S is a dangerous gas that can cause severe health problems or even death. Training ensures that individuals understand the risks, detection methods, and proper safety procedures to mitigate exposure.

What are the OSHA hydrogen sulfide exposure limits?OSHA has established exposure limits for Hydrogen Sulfide to protect workers from its toxic effects. The permissible exposure limit (PEL) is 20 parts per million (ppm) as a ceiling concentration, and a 10-minute maximum peak of 50 ppm.

How can H2S be detected?Hydrogen Sulfide can be detected using various methods, including fixed gas detectors, portable gas detectors, and colorimetric detection tubes. Regular monitoring and maintenance of detection equipment are essential for safety.

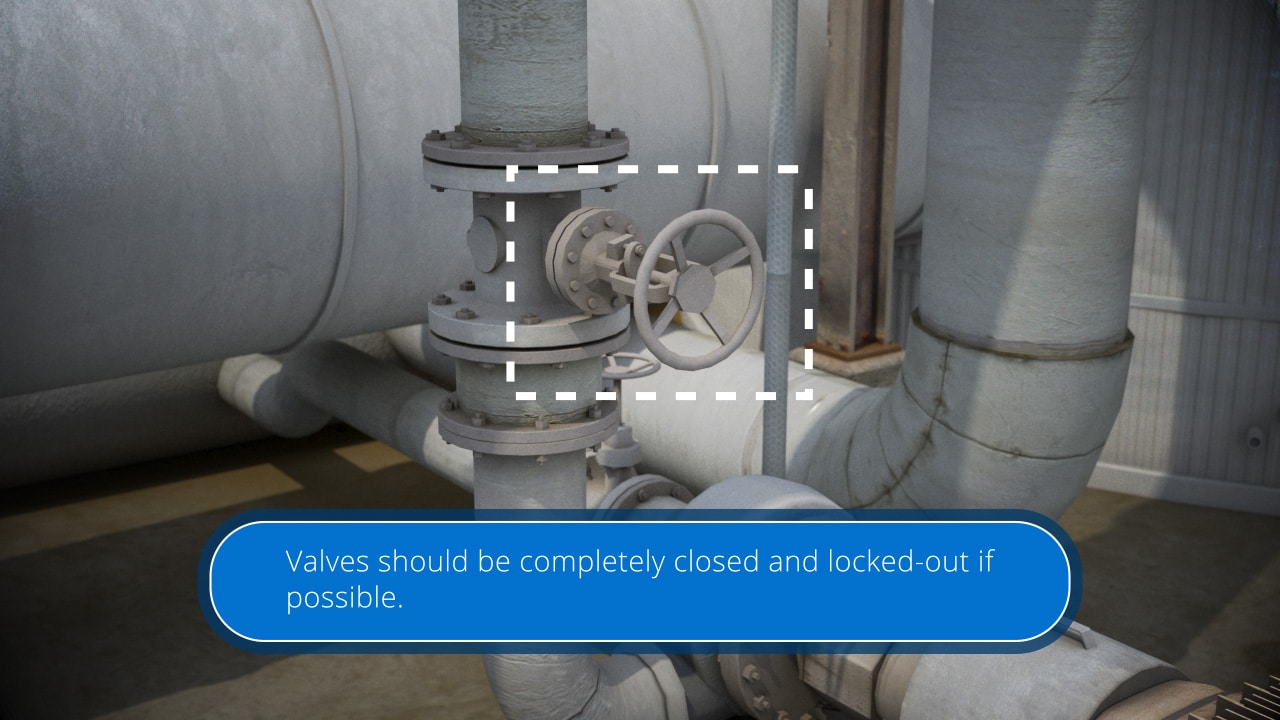

What are the prevention strategies for Hydrogen Sulfide exposure?Prevention strategies for H2S exposure include proper ventilation, regular monitoring, use of personal protective equipment (PPE), and adherence to safety protocols and training.

What should be done in case of Hydrogen Sulfide exposure?In case of H2S exposure, evacuate the area immediately, notify emergency responders, and follow established emergency procedures. Ensure that all personnel are trained in evacuation protocols.

Sample Video Transcript

If you hear or see a toxic gas alarm go off, you should leave the area immediately. If you smell rotten eggs, you must evacuate immediately. Because H2S is heavier than air and can settle in low places, the safest place is higher ground, upwind of the exposure site. If a co-worker has lost consciousness, you should leave the area immediately and contact emergency response personnel trained to address toxic gas leaks. You should not attempt to rescue a collapsed co-worker as you will almost certainly fall victim to the toxic gas.

Additional Resources

- OSHA Hydrogen Sulfide Fact Sheet – https://www.osha.gov/sites/default/files/publications/hydrogen_sulfide_fact.pdf

- NIOSH Pocket Guide to Chemical Hazards – Hydrogen Sulfide – https://www.cdc.gov/niosh/npg/npgd0337.html

- EPA Hydrogen Sulfide (H2S) Tier Trigger Level Time chart – https://www.epa.gov/system/files/documents/2021-10/ltb_h2s_so2-and-instrumentation-charts_.pdf

Learn more about our courses, get pricing, and see our platform.