November 22, 2024 7 min read

Common Food Safety Problems

Industry:

Solution:

Addressing food safety problems in the workplace is an essential aspect of maintaining good manufacturing practices. Even if you’re a food safety leader or quality assurance expert, your organization will benefit from a comprehensive review of common food safety concerns. In this blog we’ll discuss common challenges to food safety in manufacturing, solutions to these challenges, and resources for implementing them in your own organization.

Importance of Addressing Food Safety Concerns

According to the World Health Organization (WHO), an estimated 600 million people fall ill after eating contaminated food each year. That’s almost 1 in 10 people in the world. Additionally, about 420,000 individuals die from food contamination annually.

By addressing food safety problems in your organization, you can:

- Ensure the well-being and safety of employees

- Maintain consumer confidence

- Comply with regulatory requirements

- Prevent expensive product recalls

- Reduce waste

- Decrease operation downtime caused by sanitation issues

Complete Guide to Passing a Food Safety Audit

Learn how to navigate food safety regulations and audits while ensuring compliance and protecting consumer health.

Download Guide

Food Safety Concerns Identified by the FDA

To establish a robust understanding of food safety in your organization, it’s essential to first identify food safety problems. In the following sections we’ll review issues that the U.S. Food and Drug Administration (FDA) has listed as common food safety issues.

Food Safety Problems: Contamination

Raw material contamination includes two types of cases, specifically:

- Cases in which the raw materials arrive at the facility already contaminated

- Cases in which contamination occurs at the food-processing plant

This is a catch-all category for contamination of raw materials. Common food safety issues in this category include:

- Biofilm. Biofilm is a layer of slime on the surface of food caused by bacteria. Biofilm creates an environment that allows pathogens to multiply, leading to food safety concerns.

- Condensation on pipes and other equipment. This occurs when humid air contacts cold pipes in a food processing plant. The resulting condensation can then drip from the pipes into the food product, causing contamination.

- Contamination by reworked product. Using products from one product line in another product line, also known as reworking, can cause food contamination.

- Equipment that’s hard to clean. Some equipment is difficult to clean, either because of its own design or because of how it was installed.

- Post-process contamination at manufacturing plant. Post-processing contamination can occur between the lethality treatment and packaging or post-packaging.

Food Safety Problems: Inadequate Employee Training

Inadequate training of employees can lead to a variety of food safety concerns. Food processing plants must train new employees on the minimum training requirements:

- Food safety policies

- Material covered in the plant’s written GMP policy

- Personal hygiene

- Plant sanitation policies and procedures

- Product tampering awareness and consequences

- Quality control policies

In addition to that initial training of new hires, provide employees in food processing quarterly refresher courses and additional training if any operational deficiencies are noted.

Remember that food safety/GMP training must be delivered to employees in a language that the employees understand, that training programs must be updated every year, and that employers must keep records of training.

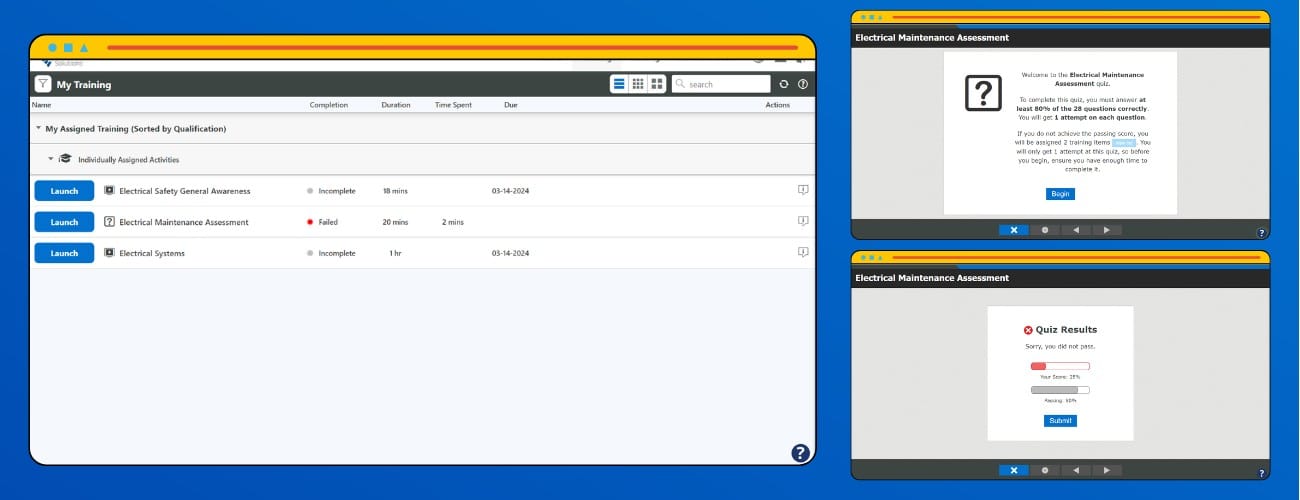

Competency Assessment

Pre-assess knowledge and skills, automatically assign training to close gaps, and verify retention of critical information.

Explore Now

Food Safety Problems: Facility Failures

Sometimes things go wrong in the workplace, leading to food safety concerns. These scenarios include:

- Food products that are labeled or packaged incorrectly

- Failure to develop a crisis management protocol

- Failure to reconcile equipment parts after repairs

- Absence of a protocol for product recovery

- Failure to perform preventive maintenance

- Improper plant design and construction

- Dead-ends in plumbing lead to accumulation of stagnant water

Implement the following tactics to avoid these common facility failures:

- Ensure that food is adequately packaged with correct labels

- Develop a crisis management protocol

- Reconcile equipment parts after repairing equipment to ensure they’re all accounted for

- Routinely perform preventive maintenance

- Keep food ingredients and products at proper, cool temperatures during processing or storage

- Ensure that your food processing plant is properly designed, built, and laid-out. Avoid floors with poor drainage and/or cross-over between the process flows of raw and finished products.

- Avoid plumbing connections that don’t drain into other areas and therefore result in sitting water

Food Safety Problems: Lack of Knowledge or Policies

Lack of knowledge about food safety issues among your workforce can lead to major problems, including:

- Lack of knowledge of welding standards. Improper welding practices can create a breeding ground for bacteria. A food processing facility must have written standards on how to conduct welding safely, train employees on those standards, and carry out welding practices according to those procedures.

- Inadequate equipment knowledge. Improper training can lead to employees not knowing how to keep equipment clean and maintained to prevent food contamination.

- Lack of allergen and chemical control programs. The lack of programs for allergen and chemical control is identified by the FDA as a leading cause of food safety concerns.

- Absent or insufficient policy for glass cleanup. Food processing plants must have a glass cleanup policy that includes properly cleaning glass containers, shielding in the event of glass breaking during production, and proper cleanup of glass in non-production areas.

Food Safety Problems: Health and Safety Issues

Ensuring proper health and safety protocol is applied in your own workforce and the facilities you partner with is essential. Make sure to look out for these key indicators of food safety issues:

- Poor employee hygiene

- Inadequate pest control

- Inadequate sanitation of plant and/or equipment

- Using unpotable water during food processing

To avoid some of these risks to food safety, utilize this checklist in your organization:

- Properly train employees in the importance of proper hygiene

- Have written employee hygiene policies and procedures

- Monitor and verify employee proper hygiene compliance

- Have a comprehensive pest management policy and program to ensure that pest control is carried out properly

- Address any poor or absent sanitation policies and procedures

- Verify that improved sanitation policies and procedures are being enacted

- Use fresh, clean, sanitary, potable water for food processing

- Ensure that your water meets local health requirements

How Vector Solutions Helps with Food Safety Training

A manufacturing food safety training program’s effectiveness is not solely determined by its ability to meet regulatory standards. At its core, it must be comprehensive, practical, and adaptable to your organization’s specific needs. Vector Solutions offers a complete library of food safety courses that provide:

- Foundational Knowledge: Employees must understand the “why” behind the practices. This includes education on the types of foodborne pathogens, their sources, and the conditions that promote their growth.

- Hands-On Skills: Practical training on the correct use of cleaning and sanitizing chemicals, equipment handling, and personal hygiene practices.

- Problem-Solving Exercises: Scenario-based training that prepares employees to identify and address sanitation issues proactively.

- Continuous Improvement: Regular updates to training content to reflect the latest in food safety research, technological advancements, and regulatory changes.

By covering these critical areas, your training programs will not only empower employees to excel in their roles but also foster a culture of safety and continuous improvement.

Request a demo and get started.