DAF System Chemicals and Chemistry – Tissue

Coagulants are used to destabilize and help remove colloidal solids from water. They work by neutralizing the surface charges on solid particles, allowing them to stick together. Flocculants can then be added to further consolidate the particles and form larger flocs. In DAF systems, air bubbles are used to float suspended solids to the surface for removal. Chemical pretreatment improves the effectiveness of the DAF process by creating flocs that are easier to float. The removed solids can be collected for re-use, as is done in tissue machine white water systems, or disposed of, as is done in wastewater treatment plants.

Request a demoCourse Details

Learning Objectives

Define and describe “coagulation” Define and describe “flocculation” Describe the functions of dissolved air, pH control chemicals, coagulants and flocculants in DAF systems

Specs

| Course Level | Intermediate |

| Languages | English |

| Compatibility | Audio, Video |

| Based on: | Industry Standards and Best Practices |

Key Questions

In systems that use both a coagulant and a flocculant, which should be added first?

The coagulant should be added first to destabilize the colloids and allow microflocs to form, and then flocculant can be added to form even bigger flocs.

Are chemical additives always necessary in dissolved air flotation systems?

DAF systems can sometimes effectively remove suspended solids without chemicals. However, they can help and their use should be determined separately for each site.

Do coagulants and flocculants require intense mixing or gentle mixing when they are added to the water?

Coagulation requires quick, intense mixing, while flocculation requires gentle mixing and sufficient retention time for the flocs to form.

What is the purpose of flocculation tubes or tanks?

These can be used to introduce chemicals into the process; they provide the proper amount of retention time and mixing energy for the chemicals being used.

Are other chemicals, besides coagulants and flocculants, used in DAF systems?

pH control (an acid or base) may be needed to maintain the feed water pH in a range suitable for the coagulant.

Sample Video Transcript

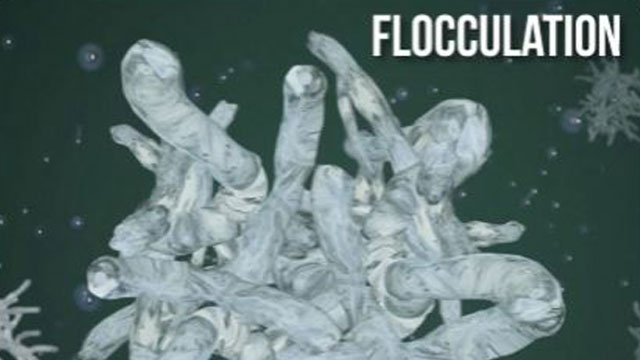

The process of bringing the microflocs formed by coagulation together into even larger aggregates or flocs is called flocculation. The flocculation process follows the coagulation process and it requires gentle mixing and sufficient retention time to allow the large flocs to form. During flocculation, the floc size of the particle aggregates continues to build and grow through additional particle collisions and interactions with added synthetic polymers. High molecular weight polymers called flocculants are added to the solution to help bridge, bend, and strengthen the flocs. These larger flocs are more buoyant and easier to float. Once they have reached a sufficient size, they can be skimmed off the surface of the DAF flotation unit.

Course Applies To

Demos + Pricing

Learn more about our courses, get pricing, and see our platform.