Tissue Machine Refining

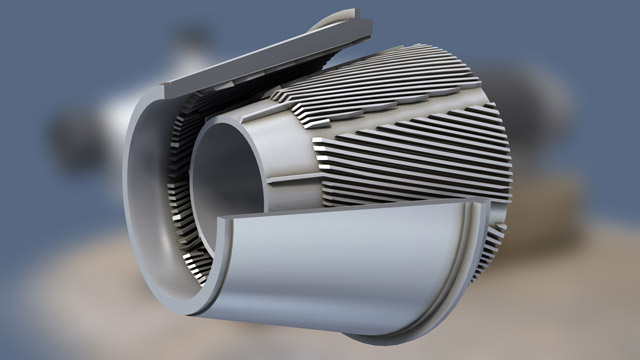

Refining is one of the critical process steps in engineering the structure of tissue as it has a major influence on fiber quality. Refining mechanically alters the fibers by brushing, hydrating, and cutting them. These actions increase the flexibility and total surface area of the fibers. The result is more area available for bonding which directly affects sheet strength, formation, and many other properties. This course will describe refining actions as they relate to disc refiners. Other refiner types will have very similar actions and results.

Request a demoCourse Details

Learning Objectives

• Describe the effects of refining on wood fibers

• Describe safety precautions associated with refiners

• State the objectives of refining

• Identify the different refiner types

• Explain how refiner plate design and gap affect tissue sheet properties

• List the different refiner control strategies

• Explain the effects of over-refining

Specs

| Course Level | Intermediate |

| Languages | English |

| Compatibility | Audio, Video |

| Based on: | Industry Standards and Best Practices |

Key Questions

What is the purpose of refining?

The primary objective of refining is to develop sheet strength.

What happens to fibers during refining?

The fiber cell walls are delaminated, allowing them to absorb more water and increasing their flexibility. External fibrillation of the fiber surfaces increases the surface area available for bonding, and some fiber cutting and creation of fines takes place.

What is it important to keep the flow rate through a refiner steady?

Flow rate determines the amount of time the fibers are available for treatment in the refiner. Low flow can lead to fiber cutting, fiber channeling in the plate grooves, and poor strength development. High flow can cause plugging and poor fiber development.

What happens if fibers are over-refined?

Over-refining causes fiber cutting, fines generation, and poor strength, with negatively affects runnability, drainage, drying demands, and production rate.

How is refining controlled?

Control strategies include power control, net specific energy control, and freeness control.

Sample Video Transcript

The primary objective of refining is to develop sheet strength. The sheet must meet the customer’s strength requirements and must be able to run on the tissue machine and converting equipment without breaking. Strength properties increase with refining due to improved bonding from fiber flexibility and external fibrillation. Although it has a positive impact on strength, too much refining can have a negative impact on desirable tissue attributes, such as bulk, absorbency, and softness. Therefore, refining must balance strength with the other sheet properties. Also in extreme cases, overrefining will damage the fibers and result in fiber cutting, fines generation, and poor strength development. This negatively effects machine runability, reduces drainage at the wet end which increases dry demands, and ultimately, reduces production rate.

Course Applies To

Demos + Pricing

Learn more about our courses, get pricing, and see our platform.