Dregs Washing

Green liquor is created when smelt from the recovery boiler is mixed with weak wash in the dissolving tank. Any un-dissolved particulate material in the green liquor is termed “dregs”. The failure to remove these foreign materials from the green liquor can lead to many difficulties in downstream lime mud washing. This module describes the composition of dregs, the need for washing of dregs, and identifies and describes the typical equipment used for washing dregs.

Request a demoCourse Details

Learning Objectives

• Describe the composition of dregs

• Identify the sources of dregs

• Describe how dregs are washed using a drum filter

• Describe the negative impacts of dregs in the recausticizing process

• Describe the need for washing of dregs

• Describe how dregs are commonly washed and dewatered

• Identify and describe the typical equipment used for washing dregs

• Identify and describe the typical process flows in the dregs system

• Identify and describe the safety hazards associated with the dregs system

Specs

| Course Level | Intermediate |

| Languages | English, Portuguese, French, Russian |

| Compatibility | Audio, Video |

| Based on: | Industry Standards and Best Practices |

Key Questions

In the recausticizing process, what are “”dregs””?

Dregs are the undissolved particulate material in green liquor.

Why do dregs need to be removed from green liquor?

If left in the liquor, dregs would negatively affect downstream processes, including interferring with lime mud washing, increasing lime kiln energy consumption and increasing the recovery cycle dead load.

Why are dregs washed?

Separated dregs still contain cooking chemical, there is an economic value seen from recovering that chemical.

Why do dregs washers typically use a precoat?

Dregs particles are very small and quickly clog filter screens. By putting a precoat on a filter and continuously removing it, higher rates of filtration and washing can be maintained.

What are alternatives to washing dregs on a drum washer?

Dregs can be washed in a clarifier then dewatered, washed on a belt washer, or washed in a chamber filter press.

Sample Video Transcript

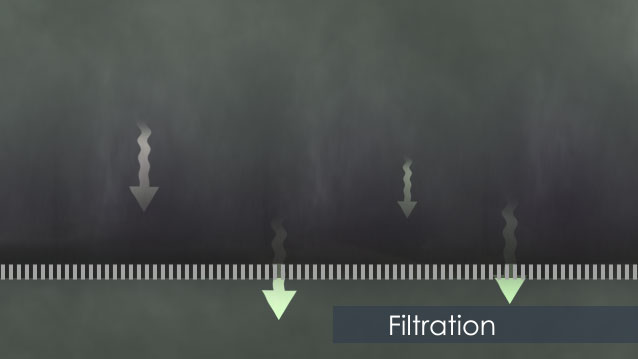

The purpose of the dregs filter is to wash and dewater the dregs. The primary element of a dregs filter is a large compartmentalized cylinder or drum with a fine mesh screen or wire covering the outer surface. A vacuum is maintained within the drum. The drum is partially submerged in a vat of dregs and liquor. An agitator in the vat keeps the dregs from settling. As the drum rotates through the dreg slurry, the mixture is pulled onto the outer wire of the drum. The liquor flows through the wire and into the drum, and a cake of dregs forms on the outer surface. Once out of the slurry, the vacuum continues to pull liquor out of the cake.

Course Applies To

Demos + Pricing

Learn more about our courses, get pricing, and see our platform.