Hydraulic System Basics

In a hydraulic system, pressure applied anywhere to a contained, incompressible fluid is transmitted undiminished throughout the fluid. This course is an introduction to hydraulic systems and their uses. It covers hydraulic theory, common components, what mechanical advantage is, and how hydraulic fluid is contaminated.

Request a demoCourse Details

Learning Objectives

• Describe hydraulic theory

• Identify and describe common hydraulic system applications

• Identify and describe basic hydraulic system components

• Describe mechanical advantage

• Describe the purpose of hydraulic fluid

• Explain the causes and effects of fluid contamination

Specs

| Course Level | Intermediate |

| Languages | English, Portuguese, French, Polish, Russian |

| Compatibility | Audio, Video |

| Based on: | Industry Standards and Best Practices |

Key Questions

What are the primary components of a basic hydraulic system?

Basic hydraulic systems combine hydraulic fluid, a reservoir, a pump, fluid lines, valves, an actuator, and a filter.

What’s the primary purpose of a hydraulic system?

Hydraulics provide a compact and reliable means of creating great force with very little energy.

What is an accumulator used for?

An accumulator stores and returns excess hydraulic fluid pressure to help minimize pressure changes in the system.

What is a ‘Mechanical Advantage’?

Mechanical advantage is the result of ‘force manipulation’. In a hydraulic system, that means that any pressure applied to a volume of fluid is transmitted with an equal amount of force throughout the entire system.

What are some common causes of hydraulic fluid contamination?

Hydraulic fluid can beome contaminated from system wear, poor or ineffective filtration, moisture buildup, or other types of environmental exposure.

Sample Video Transcript

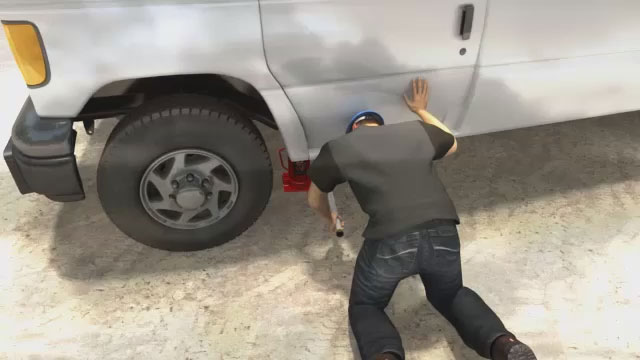

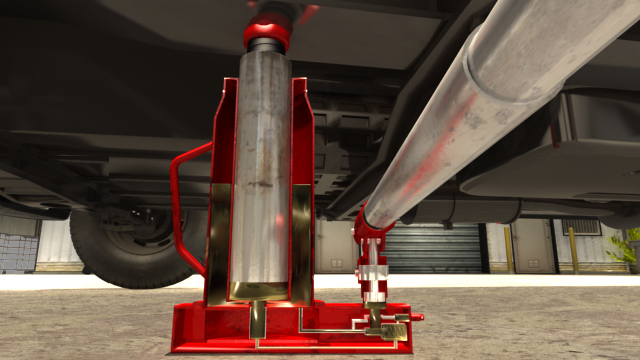

A common hydraulic bottle jack is a perfect example of mechanical advantage from force multiplication. A single pump compresses fluid with a small piston and requires little force. But that small force is transmitted and multiplied by the much larger surface area of the jack’s lifting cylinder. In this way, a hydraulic system can easily produce output forces that are 10 to 20 or more times that of the input force.

Course Applies To

Demos + Pricing

Learn more about our courses, get pricing, and see our platform.