Steam Turbine Mechanical Drives

The steam turbine generators used today produce approximately 85% of the electricity in the United States. In a typical turbine, steam flows in at a speed near 100 miles per hour and at temperatures from 400 to 950 degrees Fahrenheit. This course describes the differences between Impulse and Reaction turbines, how steam turbines are classified, and some typical operational issues associated with steam turbines.

Request a demoCourse Details

Learning Objectives

• Identify and describe safety hazards associated with the operation of steam turbines

• State the theory behind steam turbine operation

• Identify and describe the major components of a steam turbine

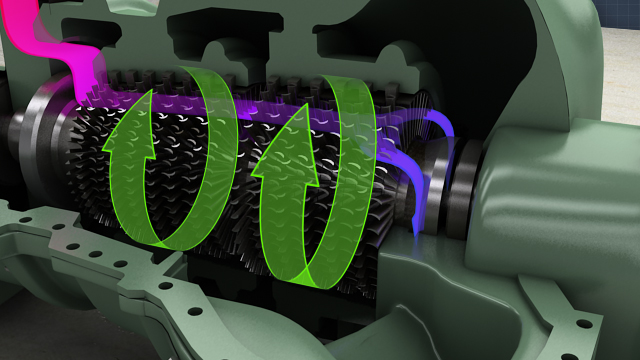

• Identify and describe the primary process flows

• Differentiate between the two types of steam turbine designs

• Differentiate between the different classifications of steam turbines

• Explain how steam turbines are lubricated

• Explain how a steam turbine’s speed and pressure is regulated

• List the different types of steam turbine protective devices

• Describe typical operational issues associated with steam turbines

Specs

| Course Level | Intermediate |

| Languages | English, Portuguese |

| Compatibility | Audio, Video |

| Based on: | Industry Standards and Best Practices |

Key Questions

What is the scientific theory behind steam turbine operation?

According to the 1st Law of Thermodynamics, energy is neither created nor destroyed; it can only be changed from one form to another.

What are the major components of a steam turbine?

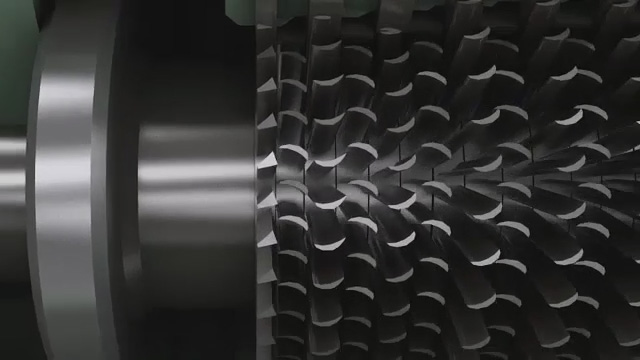

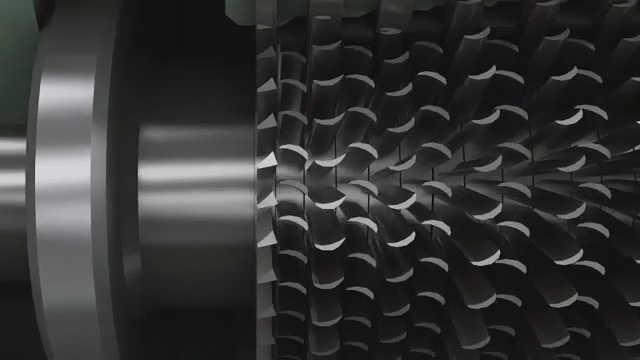

A casing; a rotor; fixed and moving blades; diaphragms; journal bearings; thrust bearings; shaft seals; an inlet valve or vales; and a speed-regulating device.

What are the two types of steam turbine designs?

Impulse and reaction. Impulse designs operate by a rotor turning due to the force of the steam striking the blades, while reaction designs operate on the principle that the rotor derives its rotational force from the steam exiting the blades.

What are some different types of steam turbine protective devices?

Overspeed trip; sentinel valves; high vibration trip; low lube oil trip; high temperature trip; low vacuum trip; and thrust bearing failure trip.

Sample Video Transcript

Impulse designs utilize fixed nozzles to decrease steam pressure and increase velocity. The nozzles also direct the steam so that it strikes the moving blades at the correct angle, to impart the greatest amount of force. Nozzles can be fixed blades shaped to act as a nozzle, or holes drilled and reamed in a steel block. Pressure only decreases in the nozzles, not in the moving blades. With the reaction design, both the fixed and moving blades are shaped like nozzles, allowing for a pressure decrease across each set of blades. This causes a velocity increase and a jetting effect when the steam exits the moving blades. Impulse designs are utilized in high-pressure stages of a turbine and reaction designs are more suited for low-pressure stages.

Course Applies To

Demos + Pricing

Learn more about our courses, get pricing, and see our platform.