Boiler Feedwater – Deaeration

A boiler recovers heat from burned fuels. This is accomplished when high pressure boiler feedwater inside tubes located throughout the boiler is heated and turns into steam or hot water. The steam or hot water is then used in a variety of facility processes. Boiler feedwater often contains dissolved oxygen, which is a common cause of corrosion inside boilers. The dissolved oxygen reacts with the boiler’s waterside metal surfaces to damage boiler tubes, headers, and drums. Corrosion can become more aggressive depending on the concentration of gas, pH, and temperature of the boiler feedwater. Therefore, the purpose of deaeration is to remove dissolved oxygen, carbon dioxide, and other non-condensable gases from boiler feedwater.

Request a demoCourse Details

Learning Objectives

• Identify and describe the safety hazards and safe work practices associated with boiler feedwater deaeration

• Explain the purpose of deaeration

• Explain how the amount of dissolved gases in water can be reduced

• Describe the function of tray-type and spray-type deaerators

• Identify and describe the key equipment and process flows associated with feedwater deaeration

• Describe the purpose of oxygen scavengers

Specs

| Course Level | Intermediate |

| Languages | English, Portuguese, French, Russian |

| Compatibility | Audio, Video |

| Based on: | Industry Standards and Best Practices |

Key Questions

Explain the purpose of deaeration?

the purpose of deaeration is to remove dissolved oxygen, carbon dioxide, and other non-condensable gases from boiler feedwater.

How can the amount of dissolved gases in water be reduced?

By increasing the temperature of the water and by decreasing the concentration of the gas in the vapor above the water

How does a tray-type deaerator function?

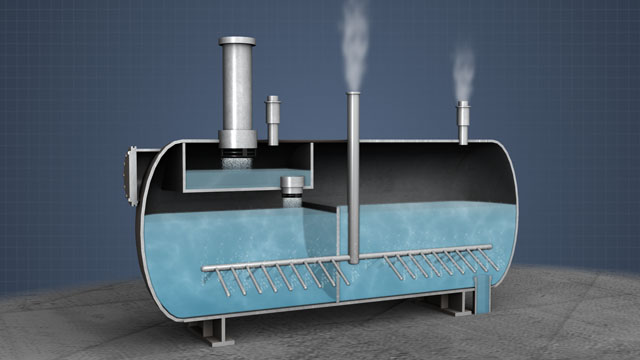

Boiler feedwater is commonly sprayed from the nozzles on top of several rows of trays. The feedwater then flows down through perforations in the trays. As feedwater passes through, steam enters under the trays heating the feedwater and removing the dissolved oxygen.

How does a spray-type deaerator function?

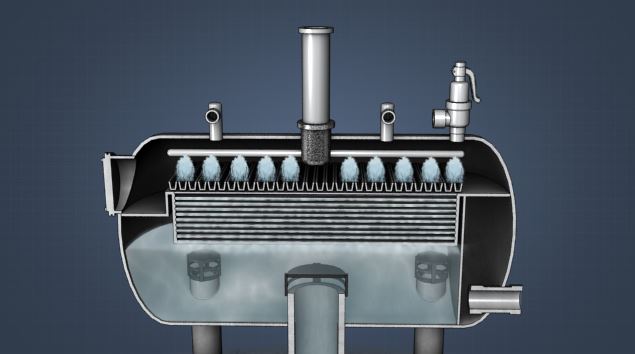

Nozzles typically spray feedwater in from the top of a steam environment. The feedwater is first preheated with steam to prepare the dissolved gases to be driven out. Then, the feedwater passes into a deaerating or “scrubbing” section, which uses steam to strip the dissolved gases from the feedwater.

What are oxygen scavengers?

Oxygen scavengers are added to the feedwater, usually in the storage tank of the feedwater, to remove the trace amount of oxygen escaped from the deaerator. The most commonly used oxygen scavenger is sodium sulfite.

Sample Video Transcript

The spray-type is also referred to as the spray-scrubber type, because a separate scrubbing section is used to provide additional steam water contact after spraying. In this type, nozzles typically spray feed water in from the top of a steam environment. The feed water is first preheated with steam to prepare the dissolved gases to be driven out. Then, the feed water passes into a deaerating, or scrubbing section, which uses steam to strip the dissolved gases from the feed water. The feed water is pumped from the bottom of the deaerator and sent to the boiler, and the gases are vetted from the top.

Course Applies To

Demos + Pricing

Learn more about our courses, get pricing, and see our platform.