Paper Machine Winder Safety

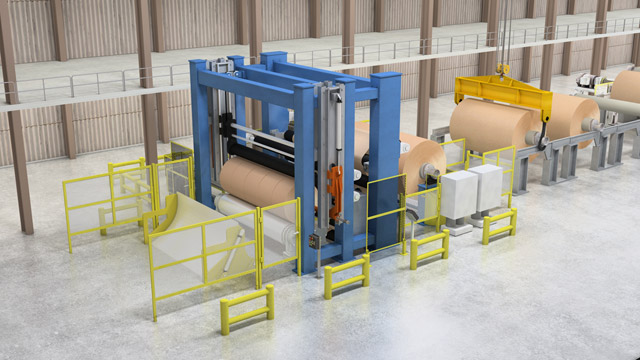

Eliminating hazards is the best way to ensure the safe operation of paper and board machine winders and rewinders. Machine guarding and safety devices, interlocks, and controls are next. Safety can also be improved by automating activities and procedures, proper training, the use of standardized procedures, and regular monitoring and maintenance of equipment and controls. Additionally, operators should know the locations of E stops, first aid cabinets, eye wash fountains, emergency showers, and fire extinguishers, and know how to use them. [course outline] The Winding Process Winding Process Challenges Winder Safety Introduction Pinch Point Hazards 1 of 2 Pinch Point Hazards 2 of 2 Nip Point Hazards 1 of 4 Nip Point Hazards 2 of 4 Nip Point Hazards 3 of 4 Nip Point Hazards 4 of 4 Cutting Hazards 1 of 2 Cutt Regulations OSHA 1910.219 (C) (4) Guarding Projecting Shaft Ends NFPA 79 Emergency Stops

Request a demoCourse Details

Learning Objectives

List devices and strategies that can be used to prevent accidents and injuries on winders Define the terms “pinch point,” “nip point,” “ingoing nip,” and “outgoing nip” Describe how machine guarding types and locations are determined for a winder Identify the locations of pinch point hazards, nip hazards, cutting hazards, fall hazards, thermal burn hazards, and slipping and tripping hazards on a winder List important safety guidelines for overhead cranes List ways to improve safety for winder operator procedures List safe behaviors to use around winders

Specs

| Course Level | Intermediate |

| Languages | English |

| Compatibility | Audio, Video |

Course Applies To

Demos + Pricing

Learn more about our courses, get pricing, and see our platform.