August 28, 2023 1 min read

Leverage the Latest Industrial Training Topics for Easy Onboarding and Upskilling

Industry:

Solution:

With nearly 2.1 million manufacturing jobs estimated to go unfilled by 2030, industrial workplaces today no longer have the luxury of loose, ad-hoc training programs.

According to the Society for Human Resource Management (SHRM), employee turnover can be as much as 50% in the first year and a half of employment. Good onboarding and training are critical to prevent churn during an employee’s first 18 months on the job, especially in industrial workplaces, where employees have to quickly familiarize themselves with standard operating procedures and hit the ground running.

Leveraging online training for employee onboarding and continuous skill development proves highly advantageous, ensuring that your team can quickly educate new hires about the industry, familiarize themselves with their responsibilities, standard operating procedures, and best practices for working with and maintaining equipment at their facility.

As a leading provider of online learning solutions, Vector Solutions not only offers comprehensive courses to empower employees to develop the skills needed to work successfully and safely in manufacturing and industrial environments but also regularly updates them to align with evolving best practices and standards.

Explore the Newest Maintenance and Operations Courses Offered by Vector Solutions

Simplify Onboarding with Operator Responsibilities Training

New hires may not be familiar with the ins and outs of a busy industrial plant and production processes. To maximize production output and increase quality and safety, plants must provide newly hired operators with training on their responsibilities within the workplace.

Investing in operator training improves overall workplace safety by preventing unskilled operators from trying to control heavy equipment. With training, teams learn the skills to know how to get the most out of their equipment, leading to greater uptime and more efficient operations.

A strong onboarding program for operators provides workers with an overview of their typical responsibilities, including monitoring and maintaining equipment, process variables, safety regulations and procedures that must be followed for routine operations as well as in emergency situations, analyzing operational trends and data to determine conditions of equipment, and how to communicate effectively with other plant personnel.

Vector Solutions’ new Operator Responsibilities training series covers all these topics and more to help new operators gain the skills they need to operate process systems and lay the groundwork for successful careers:

- Operator Responsibilities: Introduction

- Operator Responsibilities: Plant Production and Safety

- Operator Responsibilities: Trends, Maintenance, and Emergencies

- Operator Responsibilities: Communication

- Operator Responsibilities: Outside Operator Responsibilities

- Operator Responsibilities: Control Room Responsibilities

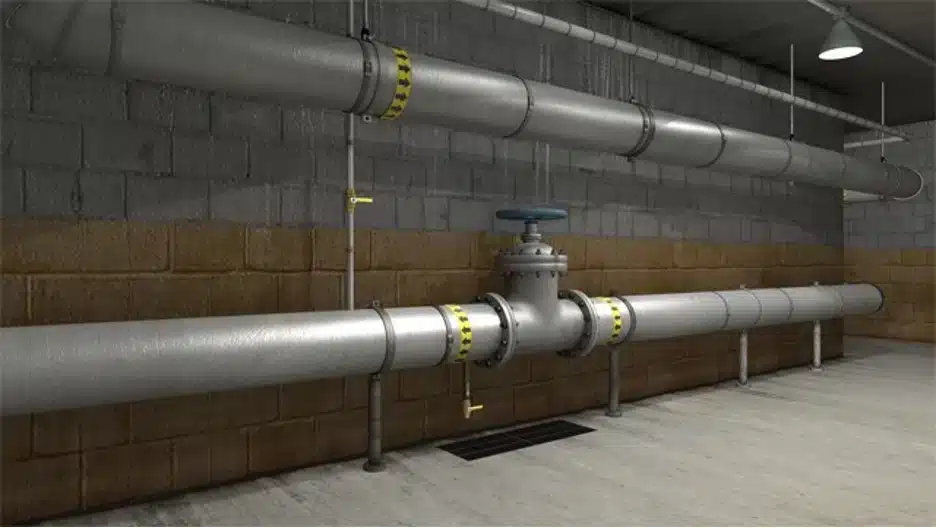

Upskill Teams on Valve Types, Maintenance, and Troubleshooting

It’s no secret that valves are an incredibly versatile and nearly ubiquitous piece of equipment that can be found throughout industrial facilities. Companies know that their valves need maintenance, but they don’t always have the personnel or the skills to effectively perform this work internally. Having a better understanding of how to install the appropriate type of valve from the beginning, troubleshooting them once they are installed, and keeping them in effective working order improves the safety, efficiency, and profitability of any plant. There are many benefits to providing employees with a strong working knowledge of valves, including:

- Better Allocation of Resources. Instead of outsourcing technical work such as maintenance, repairs, or overhauls, it may be more cost-effective and quicker for a plant’s own staff to carry out certain work on them internally. By building teams’ technical knowledge of valves over time, organizations can make better use of their maintenance budget without relying on external expertise.

- Reduced Downtime. Techs must be able to identify, evaluate and solve problems with valves while on the job. These skills are vital, as costs of downtime can significantly impact a business’ bottom line. According to Processing Magazine, one plant saved nearly $100,000 by proactively detecting and addressing a developing issue with a control valve before it shut down the unit. In-depth valve training leaves your staff better equipped to spot and fix problems before they impact production.

- Improved Safety. Preventative maintenance performed by properly trained technicians is a crucial step that facilities can take to retain the safety of equipment and personnel. Keeping valves well-maintained reduces risks of an emergency and of the catastrophic consequences—such as an explosion or release—that could result from a valve malfunction.

Vector’s new curriculum of valve courses provide teams with a great understanding of the different types of valves and their uses, how they work, and the types of problems that technicians might encounter with them while on the floor. These courses all have modern 3D graphics to illustrate the insides of valves that a worker typically couldn’t see without taking one apart or out of service.

Vector Solutions is committed to empowering and helping manufacturers and industrial organizations to be safe, knowledgeable, and compliant. As organizations hone and develop the skills and expertise of their workforce, they position themselves to continue to thrive in a competitive landscape.

Industrial Maintenance Online Training Library

Improve performance and reduce downtime with preventative maintenance programs

View library