March 13, 2018 18 min read

3 Required Parts of an Energy Control Program

Industry:

Solution:

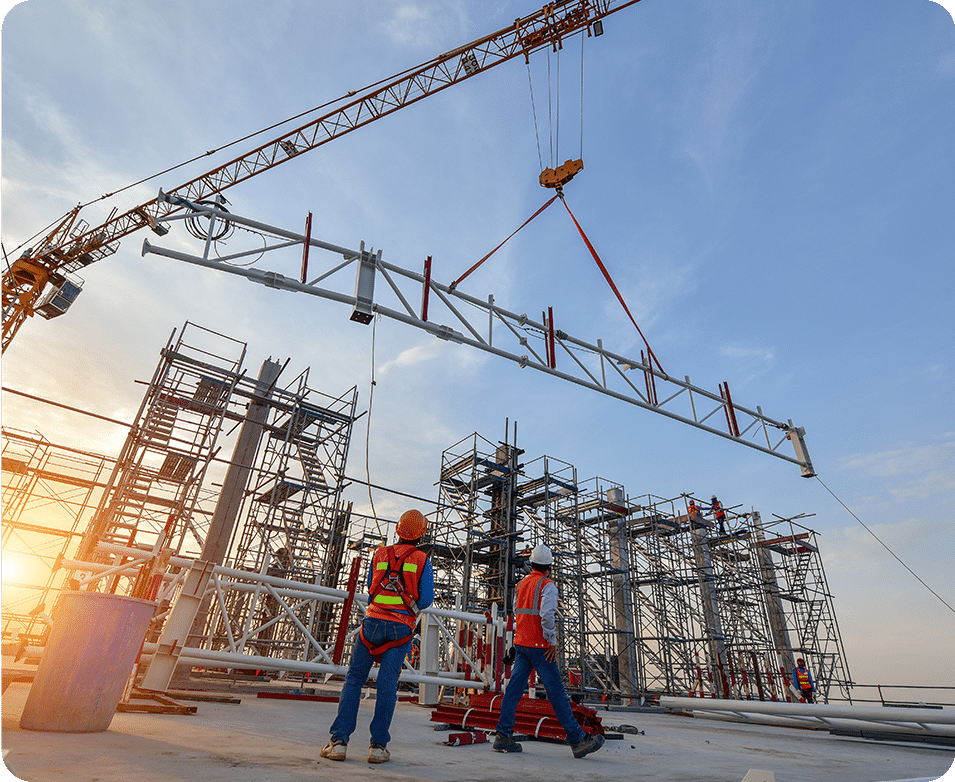

OSHA’s standard for the control of hazardous energy, also known as lockout-tagout or LOTO, is 1910.147. As the regulation explains in 1910.147(a)(1)(i), “This standard covers the servicing and maintenance of machines and equipment in which the unexpected energization or start up of the machines or equipment, or release of stored energy, could harm employees. This standard establishes minimum performance requirements for the control of such hazardous energy.”

In 1910.147(c)(1), the regulation explains that “the employer shall establish a [energy control] program consisting of energy control procedures, employee training and periodic inspections to ensure that before any employee performs any servicing or maintenance on a machine or equipment where the unexpected energizing, startup or release of stored energy could occur and cause injury, the machine or equipment shall be isolated from the energy source and rendered inoperative.”

So the energy control program required by OSHA’s Control of Hazardous Energy/Lockout-Tagout regulation requires the employer’s program to have three parts: (1) energy control procedures; (2) employee training; and (3) periodic inspections.

We’ll look at each of those three required parts of an energy control program more closely in this article.

As we do, we’ll draw some materials from two of our online safety training courses related to lockout-tagout:

Vector EHS Management Software empowers organizations – from global leaders to local businesses – to improve workplace safety and comply with environmental, health, and safety regulations.

Learn more about how our software can save you valuable time and effort in recording, tracking, and analyzing your EHS activities.

Learn more about how we can help:

- Incident Management Software →

- EHS Inspection Software →

- Key Safety Metrics Dashboard →

- Learning Management System (LMS) and Online Training Courses →

- Mobile Risk Communication Platform

Download our EHS Management Software Buyer’s Guide.

Energy Control Programs–The Purpose

We’ve already covered the fact that in 1910.147 OSHA requires employers establish a hazardous energy control program and that the program must include energy control procedures, employee training, and periodic inspections. And that’s what this article will focus on.

But before we begin, it’s a good idea to step back and remind ourselves the purpose of controlling hazardous energy. Here’s how OSHA puts it in 1910.147:

…to ensure that before any employee performs any servicing or maintenance on a machine or equipment where the unexpected energizing, startup or release of stored energy could occur and cause injury, the machine or equipment shall be isolated from the energy source and rendered inoperative.

First Requirement of a Hazardous Energy Control Program: Energy Control Procedures

The first requirement is to have a set of energy control procedures for employees to follow.

As OSHA explains in 1910.147, employers must develop and document these procedures. In addition, employees must utilize these procedures to control the release of hazardous energy at any time when they’re engaged in the type of work activity described in the 1910.147 standard.

The energy control procedures must “clearly and specifically” outline the:

- Scope

- Purpose

- Authorization

- Rules

Techniques to be utilized for the control of hazardous energy.

In addition, the employer’s energy control procedures must explain the means by which the employer will enforce compliance, which may include the following and other compliance methods:

- A statement that clearly and specifically explains the intended use of the energy control procedure

- Specific step-by-step explains of how to shut down, isolate, block, and secure machines or equipment to control hazardous energy before performing maintenance

- Specific step-by-step explains of how to place, remove, and transfer lockout devices and/or lockout-tagout devices during hazardous energy control

- An explanation of who’s responsible for lockout and/or lockout-tagout devices

- Specific steps to perform in order to test and confirm that the energy isolating and controlling measures have been effective

OSHA and 1910.147 provides an exception in which the employer does not need to document the required procedure for a specific machine or equipment if all of the following exist:

- The equipment/machine has no potential for stored or residual energy or the re-accumulation of stored energy after shutdown that could harm employees

- The equipment/machine has a single source of energy that can be readily identified and isolated

- Isolating and locking out that energy source (above) will completely de-energize and deactivate the equipment/machine

- The equipment/machine is isolated from that energy source (above) and is locked out during servicing or maintenance

- A locked-out condition on the equipment/machine can be achieved with a single lockout device

- The authorized employee performing the service or maintenance has exclusive control of the lockout device

- The process of servicing or maintenance creates no hazard for other employees

- The employer using this exception has had no accidents involving the unexpected activation or re-energization of the equipment/machine in question during servicing or maintenance

Second Requirement of a Hazardous Energy Control Program: Employee Hazardous Energy Control Training, Retraining, and Communication

The second part that OSHA requires for an energy control program is employee training, including training, retraining, and associated communication about the hazardous energy control program.

As explained in 1910.147(c), the employer must provide training so that employees understand both the purpose and the function of the energy control program. In addition, training must help employees develop the knowledge and skills necessary to safely apply, use and remove energy controls.

OSHA breaks down the energy control training that workers must receive based on their role in the energy control process as explained below.

All authorized employees must be trained to recognize sources of hazardous energy, to know the type and type and magnitude of the energy in the workplace, and to know the methods and means necessary for energy isolation and control. (Note: OSHA defines an authorized employee as “An employee who locks or tags machines or equipment in order to perform servicing or maintenance.”)

Here’s a short sample of our online safety training lockout-tagout for authorized employees course (below).

All affected employees must be trained in the purpose and use of the energy control procedure. (Note: OSHA defines an affected employee as “An employee who is required to use machines or equipment on which servicing is performed under the Lockout/Tagout standard or who performs other job responsibilities in an area where such servicing is performed.”)

Here’s a short sample of our online safety training lockout-tagout for affected employees course (below).

All other employees whose work operations are or may be in an area where energy control procedures may be utilized, must be trained about the hazardous energy control procedure, and about the rule against attempting to restart or reenergize machines or equipment that are locked out or tagged out.

Training and Tags

When tagout systems are used, employees must also be trained about the limits of tags, including:

- Tags DO NOT provide the physical restraint on an energy isolating device that a lock does, and they’re essentially just warning devices–nice information, but not a foolproof method.

- When a tag is attached to an energy isolating device, employees should not remove that tag without authorization of the authorized person who’s responsible for the tag

- When a tag is attached to an energy isolating devices, employees should never act to bypass or defeat it and should not ignore it

- All tags must be clearly legible and must be capable of being understood by all three classes of employees already mentioned (authorized employees, affected employees, and all other employees whose work operations are or may be in the area)

- Tags must be attached securely to energy isolating devices so they can’t be accidentally knocked off or otherwise detached

- Tags and their attachments must be made of materials that withstand and are appropriate for the environmental conditions in the workplace

- Tags can make things seem safer than they really are, providing a false sense of security. Employees must understand the true meaning of tags within the larger context of the energy control program

Retraining on Hazardous Energy Control Programs and Procedures

In addition, in 1910.147 OSHA spells out the following requirements for retraining of employees in regards to hazardous energy control programs:

- Employers must provide retraining for all authorized and affected employees whenever job assignments change, machines change, energy control procedures change, or equipment or processes that present a new hazard are implemented.

- In addition, retraining must be conducted whenever the employee has reasons to believe “there are deviations from or inadequacies in the employees knowledge or use of the energy control procedures,” including when such inadequacies are detected during periodic inspections (described below).

The purpose of the retraining is to re-establish the employee’s proficiency in the energy control program/procedures and/or to introduce new or revised control methods and procedures.

Training Certification for Hazardous Energy Control Training

As explained in 1910.147(c)(7)(iv), the employer must certify that employee hazardous energy control training(a) has been completed and (b) is being kept up to date. The certification must include each employee’s name and the date(s) of training.

Third Requirement of a Hazardous Energy Control Program: Periodic Inspections of Energy Control Procedures in Operation

The third and final requirement of an energy control program at work is an ongoing series of periodic inspections of the energy control procedures in operation.

Employers must periodically inspect the energy control program and energy control procedures to ensure that the requirements of 1910.147 are being followed.

OSHA spells out the specific requirements for periodic energy control procedure inspections in 1910.147(c)(6). They include:

- The inspections must occur at least every year (annually).

- The inspection must be performed by an authorized employee who IS NOT the authorized employee (or employees) that use the energy control procedure being inspected.

- If any deviations or inadequacies in the energy control procedure are identified during the inspection, they must be corrected.

- If lockout is used for energy control, the inspection must include a review of the authorized employee’s responsibility under the energy control procedure inspected. That review should take place between the inspector and the authorized employee (who uses the energy control procedure).

Certification of Hazardous Energy Control Procedure Inspections

The employer must certify that these periodic inspections of the energy control program and its procedures have been performed. The certification must identify the equipment/machine for which the energy control procedure is used, the date of the inspection, the name of the employees included in the inspection, and the name of the person performing the energy control procedure inspection.

Additional Materials on Hazardous Energy Control, Energy Control Programs, and Lockout/Tagout

You may also find the following resources helpful:

- OSHA Control of Hazardous Energy Safety and Health Web Page

- OSHA LOTO (Lockout-Tagout) eTool

- LOTO Safety: The Six Steps of Lockout-Tagout

- Helpful Lockout-Tagout Information

- Interactive Lockout-Tagout Glossary

Conclusion: The Three Major OSHA Requirements for Energy Controls Programs

We hope you found this article about energy control programs and OSHA’s requirements for them helpful. Let us know if there’s anything more we can assist with.

Otherwise, have a great day and we’ll see you soon, we hope!

EHS Software Buyer's Guide

Download Now